Contents. Valve assemblies - Valve Testing.pdf · Contents 1. Applicable Standards 2. Summary of...

Transcript of Contents. Valve assemblies - Valve Testing.pdf · Contents 1. Applicable Standards 2. Summary of...

1

Contents

1. Applicable Standards

2. Summary of Tests According to EN 14141

3. Pressure Testing of Valves

2

1. APPLICABLE STANDARDS

• ISO 14313 “Petroleum and Natural Gas Industries – Pipeline Transportation Systems – Pipeline Valves”

• EN 14141 “Valves for Natural Gas Transportation for Pipelines – Performance Requirements and Tests”

ISO 14313 specifies requirements and gives recommendations for the design, manufacturing,

testing and documentation of ball, check, gate and plug valves for application in pipeline systems.

EN 14141 is the European performance standard of valves for use in pipelines for transportation of natural gas in accordance with EN 1594. The significant properties of valves designed for a special application are defined by performance requirements accompanied by the description of tests to be carried out to give proof that the valve meets the performance requirements of this European Standard. A type test is included in this standard to satisfy the requirements of EN 1594.

3

• Beside the requirements described in these two standards additional requirements are usually described in Owner issued valve specifications which cover and/or clarify issues such as:

- Shell Design (material thickness welded or bolted design etc.)

- End Connections (butt welded or flanged, material weldability requirements)

- Dimensions (lengths, Internal Diameters)

- Valve Operation (Limit Stops, Valve Stem, Actuator Type)

- Valve Manufacturing Details

- Valve Body Connections (Type of Connections, Connection Sizes, Lifting Lugs)

- Materials for all Valve Parts and Required Certification

- Welding and Non Destructive Testing

- Pressure Testing

- Fire Testing

- Coating

- Marking

4

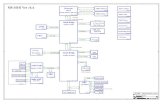

2. SUMMARY OF TESTS ACCORDING TO EN 14141

5

6

7

3. PRESSURE TESTING OF VALVES

• Stem Back Seat Test.

Testing shall be performed prior to shell testing. Where a valve has a stem backseat feature, testing of the backseat shall commence with the seat free. Self energized packing or seals shall be removed unless a test port is provided for this test.

The valves shall be filled with the ends closed off and the obturator in the partially open position until leakage of the test fluid around the stem is observed. The backseat shall then be closed and a minimum pressure of 1 ,1 times the valve pressure rating is applied for the test duration

Monitoring for leakage shall be through a test access port or by monitoring leakage around the loosened packing. No visible leakage is permitted at this test pressure.

8

• Hydrostatic Shell Test.

Hydrostatic shell testing shall be performed on the fully assembled valve prior to painting

Valves shall be closed off and the obturator placed in the partially open position during the test. If specified by the purchaser, the method of closing the ends shall permit the transmission of the full-pressure force acting on the end blanks to the valve body. Where present, external relief valves shall be removed and their connections plugged.

The test pressure shall be 1,5 or more times the valve pressure rating. The duration shall not be less than that specified in the table below:

9

• Hydrostatic Shell Test (continued).

No visible leakage is permitted during the hydrostatic shell test. After hydrostatic shell testing, external relief valves shall be (re)fitted to the valve. The connection to the valve body shall be tested at 95% of the set pressure of the relief valve for 2 minutes for valve sizes up to and including DN 100 (NPS 4), and 5 minutes for valve sizes DN 150 (NPS 6) and larger. The relief valve connection shall be free of visible leakage during this period.

Where provided, the external relief valve shall be set to relieve at the specified pressure and tested. The set pressure of relief valves shall be between 1.1 and 1.33 times the valve pressure rating.

10

• Hydrostatic Seat Test (continued).

Leakage for soft-seated valves and lubricated plug valves shall not exceed IS0 5208 Rate A (no visible leakage). For metal-seated valves the leakage rate shall not exceed IS0 5208 Rate D, except that the leakage rate during the seat test shall not be more than two times IS0 5208 Rate D unless otherwise specified. Specific test procedures are described in the standard for various types of block valves (i.e. Unidirectional, Bidirectional, Twin Seat, Double Block and Bleed etc.)

11

Hydrostatic Seat Test.

Lubricants shall be removed from seats and obturator sealing surfaces except, by agreement, for assembly lubricants for metal-to-metal contact surfaces.

The test pressure for all seat tests shall not be less than 1.1 times the valve pressure rating. The test duration shall be in accordance with the following table:

12