˘ˇ ˆ˙ - US EPA · PDF fileNOX Control Technologies for the Cement Industry FINAL...

Transcript of ˘ˇ ˆ˙ - US EPA · PDF fileNOX Control Technologies for the Cement Industry FINAL...

�

�

�

�

�

�

�

������������ �����������������������

��������������������

�

����������� �

�

�

�

�

�

EPA-457/R-00-002

September 2000

NOX Control Technologies for the Cement Industry

FINAL REPORT

EPA Contract No. 68-D98-026

Work Assignment No. 2-28

EC/R Project No. ISD-228

Prepared for:

Mr. David Sanders

Ozone Policy and Strategies Group

Air Quality Strategies and Standards Division, MD-15

Office of Air Quality Planning and Standards

U.S. Environmental Protection Agency

Research Triangle Park, NC 27711

Prepared by:

Rebecca Battye, Stephanie Walsh, Judy Lee-Greco

EC/R Incorporated

1129 Weaver Dairy Road, Suite AA-1

Chapel Hill, NC 27514

September 19, 2000

i

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 PURPOSE OF THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 METHODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 REFERENCE FOR CHAPTER 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 UNCONTROLLED NOX EMISSIONS FROM CEMENT KILNS . . . . . . . . . . . 2

2.2 NOX CONTROL TECHNOLOGY FOR CEMENT KILNS . . . . . . . . . . . . . . . . . 4

2.2.1 Process Control Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Combustion Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.3 NOX Removal Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.4 NOX Control Efficiencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 CONTROL COSTS AND COST EFFECTIVENESS . . . . . . . . . . . . . . . . . . . . . . 8

2.4 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 INDUSTRY DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 BACKGROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 TYPES OF CEMENT PRODUCED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 INDUSTRY CHARACTERIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 Description of the Cement Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.2 Overview of Cement Manufacturing Process . . . . . . . . . . . . . . . . . . . . . 21

3.3.3 Raw Materials and Kiln Feed Preparation . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.4 Pyroprocessing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.4.1 Wet Process Kilns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.4.2 Dry Process Kilns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.4.3 Suspension Preheaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.4.4 Precalciner Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.5 Finish Grinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.6 Quality Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.7 Emission Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.0 UNCONTROLLED NOX EMISSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 MECHANISMS OF NOX FORMATION IN CEMENT MANUFACTURING . . . 29

4.1.1 Thermal NOX Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.2 Fuel NOX Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.3 Feed NOX Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ii

TABLE OF CONTENTS (continued)

4.2 FACTORS AFFECTING NOX EMISSIONS IN CEMENT MANUFACTURING . 32

4.2.1 NOX Formation in the Kiln Burning Zone . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.2 NOX Formation in Secondary Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.2.1 Suspension Preheater (SP) Kilns with Riser Duct Firing . . . . . . 35

4.2.2.2 Precalcining Kiln Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2.3 Energy Efficiency of the Cement-Making Process . . . . . . . . . . . . . . . . . 36

4.3 AVAILABLE DATA FOR UNCONTROLLED NOX EMISSIONS FROM CEMENT

MANUFACTURING FACILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.0 NOX CONTROL TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1 PROCESS CONTROL MODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.1 Combustion Zone Control of Temperature and Excess Air . . . . . . . . . . . . 54

5.1.2 Feed Mix Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1.2.1 Reduction of Alkali Content of Raw Feed . . . . . . . . . . . . . . . . . 55

5.1.2.2 CemStar Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.1.3 Kiln Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.1.4 Increasing Thermal Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2 COMBUSTION MODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2.1 Staged Combustion of Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2.1.1 Flue Gas Recirculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.1.2 Low-NOX Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.2 Staged Combustion of Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.2.1 Preheater/Precalciner and Tire Derived Fuel . . . . . . . . . . . . . . . 62

5.2.2.2 Low-NOX Precalciners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.2.2.3 Mid-Kiln Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3 NOX REMOVAL CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.3.1 Selective Catalytic Reduction (SCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.3.2 Selective Noncatalytic Reduction (SNCR) . . . . . . . . . . . . . . . . . . . . . . . . 70

5.3.2.1 Biosolids Injection (BSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.3.2.2 NOXOUT® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4 SUMMARY OF EUROPEAN EXPERIENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.5 SUMMARY OF APPLICABLE NOX CONTROL TECHNOLOGIES . . . . . . . . . . 76

5.6 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.0 COSTS OF NOX CONTROL TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.1 COST CALCULATION METHODOLOGY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.1.1 Model Plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.1.2 Capital Cost Estimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

iii

TABLE OF CONTENTS (continued)

6.1.3 Annual Operating Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.1.3.1 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.1.3.2 Operating and Supervising Labor . . . . . . . . . . . . . . . . . . . . . . . . 87

6.1.3.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.3.4 Overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.3.5 Property Taxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.3.6 Insurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.3.7 Administrative Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.3.8 Capital Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.2 COSTS OF NOX CONTROL APPROACHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.2.1 Process Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.2.1.1 Combustion Zone Control of Temperature and Excess Air . . . . 89

6.2.1.2 CemStar Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.2.2 Combustion Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.2.2.1 Low NOX Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.2.2.2 Mid-Kiln Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.2.3 NOX Removal Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.3.1 Biosolids Injection Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.3.2 NOXOUT®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.2.3.3 Selective Catalytic Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.3 COST EFFECTIVENESS OF NOX CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.3.1 CemStar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.3.2 Low NOX Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.3.3 Mid-Kiln Firing of Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.3.4 Preheater/Precalciner Tire Derived Fuel . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.3.5 Biosolids Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3.6 Selective Noncatalytic Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3.7 Selective Catalytic Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3.8 Summary of Cost Effectiveness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.4 REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

iv

LIST OF TABLES

Table 2-1. Summary of Updated Uncontrolled NOX Emissions Data and the

Corresponding 1994 Act Document Estimates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2-2. Comparison of 1994 Act Document and Current NOX Control Technology

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2-3. Summary of Cost Effectiveness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3-1. Basic Clinker Compounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3-2. United States Cement Company Capacities in 1998 . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 3-3. United States 1998 Clinker Capacities by State . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 4-1. Calculated Equilibrium Concentrations (in ppm) of NO and NO2

in Air and Flue Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 4-2. NOX Emissions Data Used to Develop 1994 Act Document . . . . . . . . . . . . . . . . . . 38

Table 4-3. Summary of Additional NOX Emission Data for Different Kiln Types . . . . . . . . . . 48

Table 4-4. Comparison of Emission Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 4-5. NOX Emission Factors for Different Kiln Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 5-1. Results of Short-term Cemstar Tests on a Preheater/precalciner Kiln . . . . . . . . . . . 56

Table 5-2. Results of Cemstar Tests on a Wet Kiln . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-3. NOX Emissions from a Precalciner Equipped with a Low-NOX Burner . . . . . . . . . . 60

Table 5-4. NOX Emissions Before and after Installation of Pyro-jet Low-NOX Burners . . . . . . 61

Table 5-5. NOX Emissions with 3 Channel and Rotaflam® Low-NOX Burners . . . . . . . . . . . . . 61

Table 5-6. Emissions Before and after Installation of a Rotaflam® Burner on a Wet Kiln . . . . 62

Table 5-7. Emissions from Kilns with Mid-kiln Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 5-8. Emission Reductions from Two Kilns Using NOXOUT® . . . . . . . . . . . . . . . . . . . . . 74

Table 5-9. NOX Control Techniques Summary from European Best Available Techniques Report75

Table 5-10. NOX Control Techniques and Applicable Types of Cement Kilns . . . . . . . . . . . . . 76

Table 5-11. Comparison of 1994 Act NOX Emissions Reductions with Newly Available

Emissions Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

v

LIST OF TABLES (continued)

Table 6-1. Cement Kiln Model Plants for Cost Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 6-2. Capital Investment Components for Emission Control Device Cost Evaluation . . . 86

Table 6-3. Annualized Cost Elements and Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 6-4. Basis for Cost Analysis of Cemstar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 6-5. Capital Costs for Retrofit Low-NOX Burners in an Existing Indirect-fired Kiln . . . 93

Table 6-6. Annualized Costs for Retrofit Low-NOX Burners in an Existing Indirect-fired Kiln 94

Table 6-7. Capital Costs for Retrofit Low-NOX Burners in an Existing Direct-fired Kiln . . . . . 96

Table 6-8. Annualized Costs for Retrofit Low-NOX Burners in an Existing Direct-fired Kiln . 97

Table 6-9. Capital Costs for Mid-kiln Firing Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 6-10. Annualized Costs for Mid-kiln Firing Conversion . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 6-11. Basis for Cost Analysis of Biosolids Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 6-12. Basis for Cost Analysis of NOXOUT® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 6-13. Capital Costs for SCR Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 6-14. Annualized Costs for SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table 6-15. Cost Effectiveness of Retrofit Low-NOX Burners in an Existing Indirect-fired

Kiln . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 6-16. Cost Effectiveness of Retrofit Low-NOX Burners in an Existing Direct-fired

Kiln . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 6-17. Cost Effectiveness of Mid-kiln Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 6-18. Cost Effectiveness of SCR Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 6-19. Summary of Cost Effectiveness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

vi

LIST OF FIGURES

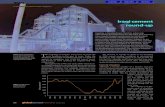

Figure 3-1. Annual clinker production. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3-2. United States and Canadian Portland Cement Locations

(December 31, 1998) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3-3. Steps in the manufacture of portland cement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3-4. Preheater/precalciner cement kiln. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4-1. Theoretical equilibrium concentrations of NO in gas from combustion

sustained in air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5-1. Schematic of low-NOX burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 5-2. Schematic of preheater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 5-3. Schematic of precalciner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 5-4. Reduction of NOX emissions from precalcining kiln system by fuel injection

in the rotary kiln gas outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 5-5. Schematic of mid-kiln firing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 5-6. Schematic of fuel injection in kiln. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 5-7. Application of SNCR in preheater kiln. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

1

1. U.S. Environmental Protection Agency. Alternative Control Techniques Document - NOX

Emissions from Cement Manufacturing. EPA-453/R-94-004. Research Triangle Park,

NC. March 1994.

1.0 INTRODUCTION

1.1 PURPOSE OF THIS DOCUMENT

The purpose of this document is to update the information in the document Alternative

Control Techniques Document - NOX Emissions from Cement Manufacturing (the 1994 ACT

document).1 This update incorporates comments received on the 1994 ACT document and

provides more recent data on emission control technologies and their costs.

This report examines uncontrolled emissions from four kiln types (wet, long dry,

preheater, precalciner). The report focuses on the current use, effectiveness, and cost of several

control technologies applicable to all or some kiln types, including CemStar, low-NOX burners,

mid-kiln firing, and selective noncatalytic reduction via biosolids injection and NOXOUT®

technology.

1.2 METHODS

Data were collected for this report primarily through site visits at cement kiln facilities;

contacts with control technology vendors, portland cement industry representatives, and state

regulatory agencies; and a literature search. Additional information was obtained through

seeking out useful sites on the internet.

1.3 ORGANIZATION

Chapter 2 presents a summary of the findings of this study. Chapter 3 provides a

description of the portland cement industry. Chapter 4 examines uncontrolled NOX emissions.

Chapter 5 presents an update on selected NOX control technologies. Chapter 6 presents an

update on control costs and cost effectiveness.

1.4 REFERENCE FOR CHAPTER 1

2

2.0 SUMMARY

This report addresses nitrogen oxides (NOX) emissions from portland cement kilns and

the current use, effectiveness, and cost of applicable control technologies. This chapter presents

a summary of updated information on uncontrolled NOX emissions from kilns and the

applicability, effectiveness, and costs of NOX control technologies. Information that is

summarized in this chapter is presented in greater depth in subsequent chapters. Section 2.1

includes a summary of current uncontrolled NOX emissions data from the four kiln types.

Section 2.2 summarizes NOX control technology emissions data. Section 2.3 presents a summary

of updated control costs and cost effectiveness for these control technologies.

2.1 UNCONTROLLED NOX EMISSIONS FROM CEMENT KILNS

In cement manufacturing, conditions favorable for formation of NOX are reached

routinely because of high process temperatures. Essentially all NOX emissions associated with

cement manufacturing are generated in cement kilns.

In cement kilns, NOX emissions are formed during fuel combustion by two primary

mechanisms:

• Oxidation of molecular nitrogen present in the combustion air, which is termed

“thermal NOX” formation, and

• Oxidation of nitrogen compounds present in the fuel, which is termed “fuel NOX”

formation.

Often the raw material feed to the kiln contains a significant amount of nitrogen compounds

which may lead to feed NOX formation similar to fuel NOX formation. Because of the high

temperatures involved in the burning or clinker formation step, thermal NOX formation provides

the dominant mechanism for NOX formation in cement manufacturing.

There are four different types of cement kilns used in the industry: wet kilns, long dry

kilns, kilns with a preheater, and kilns with a preheater/precalciner. All cement kiln systems

contain a rotary kiln. The wet, long dry, and most preheater kilns have only one fuel combustion

zone; whereas, the newer preheater/precalciner kilns and preheater kilns with a riser duct have

two fuel combustion zones. Some precalciner kilns have a third combustion zone. Since the

typical temperatures in the combustion zones are different, the factors affecting NOX formation

are also somewhat different in the different kiln types. In the primary combustion zone at the hot

end of a kiln, the high temperatures lead predominantly to thermal NOX formation; whereas, in

secondary combustion zones lower gas-phase temperatures suppress thermal NOX formation.

In addition to the specific NOX formation mechanisms, the energy efficiency of the

cement making process is also important as it determines the amount of heat input needed to

3

produce a unit quantity of cement. A high thermal efficiency would lead to less consumption of

heat and fuel, and should produce lower NOX emissions per ton of clinker, the product of the

rotary kiln.

EC/R obtained emissions data for cement kilns from state regulatory agencies in eight of

the top ten states in terms of clinker capacity: California, Florida, Indiana, Michigan, Missouri,

New York, Pennsylvania, and Texas. Table 2-1 presents a summary of the recent state emissions

data alongside a summary of the estimates used in the 1994 ACT document and the current

edition of AP-42.

TABLE 2-1. SUMMARY OF UPDATED UNCONTROLLED NOX EMISSIONS DATA

AND THE CORRESPONDING 1994 ACT DOCUMENT ESTIMATES

1994 ACT Document1 AP-42 2 Recent State Data3

Cement kiln type

Average

(lb/ton of

clinker)

Range

(lb/ton of

clinker)

(lb/ton of

clinker)

Average rate

(lb/ton of

clinker)

Range of rates

(lb/ton of

clinker)

Wet kiln 9.7 3.6 to 19.5 7.4 6.2 1.9 - 13.4

Long dry kiln 8.6 6.1 to 10.5 6.0 4.5 2.5 - 7.1

Preheater kiln 5.9 2.5 to 11.7 4.8 1.7 0.4 - 3.7

Precalciner kiln 3.8 0.9 to 7.0 4.2 2.9 1.1 - 5.6

There is substantial spread in the reported NOX emissions with significant overlap for

different kiln types. The four different cement kiln types, however, do appear to have different

levels of NOX emissions and different characteristics influencing NOX formation. Information

used to calculate NOX uncontrolled emission rates come from air emission tests at various

cement manufacturing facilities in the United States. Twenty-two tests were used to calculate the

AP-42 NOX emission factors and all of the tests are over ten years old. In addition, the majority

of these are short-term emissions tests, which do not capture the inherent variability of kiln NOX

emissions. As a result, the AP-42 NOX emission factors have a quality rating of “D” (relatively

low quality - limited data, or highly variable). When one reviews the original data summarized

in the 1994 ACT document, it is clear that the average emission rates are not unduly influenced

by outliers as evidenced by the fact that the average for each kiln type is nearly in the middle of

the range. Because the data used in the calculation of the 1994 ACT document NOX emission

rates are newer, these average emission rates may be more representative of modern kilns than

the factors presented in AP-42.4

Seven of the states that were contacted reported emissions in tons NOX/year. Six of these

states did not report production values, so kiln capacities5 were used to determine emission rates.

The kilns were assumed to operate for an average of 8,000 hours/year at maximum production

capacity. The resulting average emission rates are generally lower than the average emission

4

rates calculated in the 1994 ACT document or presented in AP-42. The lower numbers are

probably a result of using kiln capacities rather than actual kiln production values. Because of

the uncertainty surrounding the production values for the state data and because the AP-42 data

have a “D” rating, the 1994 ACT document values for uncontrolled NOX emissions from cement

kilns are used in this document. However, it should be noted that the ranges in emissions and the

average values for all three data sources generally support one another. Chapter 4 contains more

detailed information on the uncontrolled NOX emission values.

2.2 NOX CONTROL TECHNOLOGY FOR CEMENT KILNS

NOX control approaches applicable to the cement industry may be grouped in three

categories: process modifications, where the emphasis is on increased energy efficiency and

productivity; combustion control approaches, where the emphasis is on reducing NOX formation;

and NOX reduction controls, which remove the NOX formed in the combustion process.

2.2.1 Process Control Modifications

Process modifications are usually done to reduce heat consumption, to improve clinker

quality, and to increase the lifetime of the equipment (such as the refractory lining) by stabilizing

process parameters. Process modifications are applicable to all kilns and can include many

elements, such as instruction and training of the kiln operators, homogenizing raw material,

ensuring uniform coal dosing, improving the cooler’s operation, and installing new equipment.

Process modifications improve fuel efficiency, reduce operating costs, increase capacity and kiln

operational stability. Since NOX formation is directly related to the amount of energy consumed

in cement-making, improving fuel efficiency and productivity will reduce NOX emissions.

Continuous monitoring of oxygen and carbon monoxide emissions in the cement kiln

exhaust gases indicates the amount of excess air. At a given excess air level, NOX emissions

increase as the temperature of the combustion zone increases. A typical kiln combustion zone

solids temperature range is about 1430 to 1540 C (2600 to 2800 F) for completion of

clinkering reactions and to maintain the quality of the cement produced.6 The corresponding gas-

phase temperature is usually greater than 1700 C (3100 F).7 Maintaining the combustion zone

temperature at the minimum necessary value would minimize both the process energy

requirement and the NOX emissions.

Along with the appropriate temperature, it is also necessary to maintain an oxidizing

atmosphere in the clinker burning zone to ensure the quality of the clinker produced. Although a

kiln could be operated with as little as 0.5 percent oxygen in the exhaust, kiln operators typically

strive for an oxygen level of 1 to 2 percent to guarantee the desired oxidizing conditions in the

clinker burning zone. An experimental test on a cement kiln showed that by reducing excess air

from 10 to 5 percent (i.e., reducing exhaust oxygen levels from 2 to 1 percent), NOX emissions

per unit time can be reduced by approximately 15 percent.8,9

5

With state-of-the-art continuous emissions monitoring systems (CEMS) and feedback

control, excess air can be accurately controlled to maintain a level that promotes optimum

combustion and burning conditions in addition to lowering NOX emissions. Reducing excess air

levels also results in increased productivity per unit of energy consumed and thus results in an

indirect reduction of NOX emissions per unit of clinker product.

Process modifications can be highly site specific and data from one site cannot be directly

translated to other sites. Quite often a number of process modifications and combustion control

measures are implemented simultaneously. Process modifications can reduce NOX emissions in

cement kilns without any specific NOX control equipment. Some plants rely on process

monitoring and control and process modifications as a means to maintain NOX emissions within

their allowable limits. Although process controls will reduce NOX emissions in poorly operated

kilns, for the purposes of this document, such approaches are considered necessary for proper

kiln operation and are not specifically considered as NOX control techniques, except as noted

below for CemStar.

One process modification that can be quantified is the CemStar process, which can reduce

NOX emissions at any type of kiln by the addition of a small amount of steel slag to the raw kiln

feed. Steel slag has a low melting temperature and is chemically very similar to clinker. Since

many of the chemical reactions required to convert steel slag to clinker have already taken place

in a steel furnace, the fuel needed to convert steel slag into clinker is low. The decreased need

for limestone calcination per unit product and improved thermal efficiency of the process both

contribute to reduced thermal NOX and carbon dioxide emissions.10 CemStar is currently being

used or is in the process of being incorporated at 11 cement facilities in the United States.

CemStar requires little extra equipment and the addition of steel slag to the feed mix can result in

a reduction or elimination of the need for some mineral sources, such as shale or clay. This

process can decrease NOX emissions by 30% and can also increase production by 15 percent.10

2.2.2 Combustion Modifications

Combustion modifications are an efficient way to reduce the formation of thermal NOX.

The combustion modifications discussed in this report focus on staging the combustion to

minimize the amount of combustion that must occur at the maximum temperatures. This can be

accomplished by modifying the way oxygen or fuel is provided for combustion.

Low-NOX burner systems are available for all kiln types and rely on the staged

combustion of air. Technical literature and industry publications report NOX reduction rates of

23 to 47 percent with the installation of low-NOX burners, depending on the baseline emissions,

type of kiln, type of low-NOX burner, and operating conditions.11,12,13,14,15 In January 2000, the

Portland Cement Association (PCA) and American Portland Cement Alliance (APCA) provided

results of a survey of cement facilities where the respondents indicated 14% of the operating U.S.

kilns have already installed a low-NOX burner (81% of the facilities representing 81% of the

operating U.S. kilns responded to the survey).16,17

6

Staged combustion of fuel includes the use of preheaters/precalciners and mid-kiln firing.

Mid-kiln firing of fuels is currently installed in 21 U.S. wet and long dry cement kilns, and whole

tires are most frequently used for the mid-kiln fuel. Technical literature, industry publications,

and state emissions data for several kilns that have used or tested mid-kiln firing demonstrate

NOX reductions ranging from 28 to over 50 percent.18,19,20,21,22,23,24 Use of tire derived

supplemental fuel at a preheater/precalciner has been shown to decrease NOX emissions by 30-40

percent.25

2.2.3 NOX Removal Control

NOX removal controls destroy NOX that is formed in the combustion process. Selective

catalytic reduction (SCR) and selective noncatalytic reduction (SNCR) are two types of NOX

removal controls. Biosolids injection technology is not technically SNCR, but the chemistry and

the principles of its operation are similar. For this reason it is discussed with the other NOX

removal controls.

SCR uses ammonia in the presence of a catalyst to selectively reduce NOX emissions

from exhaust gases. SCR technology has not been used on any cement kilns in the United States,

although pilot plant trials and feasibility studies have been conducted in Europe.

SNCR relies on the reduction of NOX in exhaust gases by ammonia or urea without using

any catalyst and can achieve NOX emission reductions of 30 to 70 percent. This approach avoids

the problems related to catalyst fouling, as in SCR technology, but requires injection of the

reagents in the kiln at a temperature between 870 to 1090 C (1600 to 2000 F). At these

temperatures urea decomposes to produce ammonia which is responsible for NOX reduction.

Because of the temperature constraint, SNCR technology is only applicable to preheater and

precalciner kilns. In principle, any of a number of nitrogen compounds may be used, e.g.,

cyanuric acid, pyridine, and ammonium acetate. However, for reasons of cost, safety, simplicity,

and by-product formation, ammonia and urea have been used in most of the SNCR applications.

There have been two SNCR demonstration at full size kilns in the United States using the

NOXOUT® process.26,27 SNCR is currently operating on numerous kilns in Europe.28

Biosolids injection technology is being used in one kiln in Southern California.29,30 At

this facility, the biosolids (dewatered sewage sludge) are injected into the mixing chamber where

the flue gas streams leaving the kiln and precalciner mix. The mixing chamber offers the

benefits of good residence time in the appropriate temperature window and high mixing

effectiveness. Biosolids injection is achieving a 50 percent NOX emission reduction at this

facility.

2.2.4 NOX Control Efficiencies

An assortment of industry data, literature, and professional publications, as well as some

of the state data described above, was used to develop an estimate of emissions from cement

7

kilns using NOX control technologies. Table 2-2 presents a summary of updated control

technology emission rates alongside the emission estimates used in the 1994 ACT document.

The new emissions rates are all within or very close to the ranges established in the 1994 ACT

document. CemStar, a relatively new process that involves adding steel slag to the feed mix in a

long kiln, was not discussed in the 1994 ACT document. Emission rate reductions from the use

of CemStar averaged 33 percent. New data on low-NOX burners and mid-kiln firing tend to

support the information presented in the 1994 ACT document. Both of these technologies have

become more commonplace in controlling NOX emissions from cement kilns and improved

performance using mid-kiln firing technology has been obtained. Data were also obtained on

two SNCR technologies, biosolids injection and NOXOUT®. These technologies showed average

emission reductions of 50 and 40 percent, respectively. Additional information on SCR was not

obtained during the development of this report. Chapter 5 contains a more detailed discussion of

the NOX control technologies.

TABLE 2-2. COMPARISON OF 1994 ACT DOCUMENT AND CURRENT

NOX CONTROL TECHNOLOGY PERFORMANCE

1994 ACT Updated Emissions Data3

Possible

NOX

Emission

Reduction

(%)

Average

Emission

Reduction

(%)

Range of

Emission

Reductions

(%)

Average

Emission

Rate

(lb NOX/ton

of clinker)

Range of

Emission

Rates Found

(lb NOX/ton

of clinker)

Process Control

Modifications

<25

CemStar n/a 33 23 to 40 6.0 3.2 to 11.2

Indirect firing

with a low-NOX

burner

20 to 30 27 4 to 47 9.0a 9.0a

MKF

(wet kilns only)

20 to 40 41 28 to 59 n/a n/a

MKF

(dry kilns only)

20 to 40 33 11 to 55 3.9 2.0 to 10

TDF in a

precalcinerb

not

applicable

35 30 to 40 2.4b 2.4b

SNCR 30 to 70 BSI 50 NA 1.2b 1.2b

NOX-

OUT

40 10 to 50 NA NA

n/a - not applicablea Only one facility reported emissions in lb NOX/ton of clinker. The other data were reported in

percent.

8

b One facility in southern California provided emission reduction data for both biosolids injection

technology and firing tire derived fuel in a precalciner.

2.3 CONTROL COSTS AND COST EFFECTIVENESS

Capital and annualized operating costs as well as cost effectiveness were determined for

technologies for which detailed costs could be developed. Costs for low-NOX burners and mid-

kiln firing were developed for applicable model plants. Since there are limited cost data

available for installations of CemStar and biosolids injection, and no U.S. installations of SNCR,

the capital and annualized costs for these technologies were not developed for model plants for

purposes of this report. Costs for SCR were developed in the 1994 ACT document and are

presented again in this report. The SCR costs have not been updated or revised. All of the

capital and annualized operating costs developed for this report are based on information

provided by vendors, actual installations, and guidelines provided by the U.S. Environmental

Protection Agency/Office of Air Quality Planning and Standards (EPA/OAQPS) Control Cost

Manual.

The cost of a commercially available kiln process control system, based on existing

installations, is approximately $750,000. The resulting savings due to reduced energy and fuel

requirements and increased refractory life were estimated to be about $1.37/ton of clinker. Thus,

for a kiln producing 300,000 tons/year of clinker, the reduced cost of producing cement is

expected to recover process control installation costs in less than 2 years.

Costs for CemStar were estimated for a long wet kiln. Approximate capital investment in

1997 dollars was estimated at $1,176,000 and annualized costs estimated to be $220,000. Cost

savings associated with CemStar due to the resulting production increase are estimated to be

approximately $63 per ton times the increase in production, which is usually 5 to 10 percent.

The cost of CemStar could not be estimated on a variety of kilns because the amount of steel slag

added is completely dependent on plant-specific variables.

Biosolids injection has been installed on one kiln. The total capital investment costs for

this kiln were $1.2 million with an annual operating cost of ($322,000) per year (which includes

tipping fees for the biosolids of $5/ton). Costs for NOXOUT® technology were obtained from the

equipment vendor for two preheater/precalciner kilns. Total capital investment were $1.06

million and $1.2 million. The annualized costs for these kilns are $560,000 and $2,000,000 per

year.

Cost analysis was performed for low-NOX burners and mid-kiln firing on up to eight

different model kilns. Models 1 and 2 were wet kilns with 30 and 50 tons of clinker per hour

(ton/hour) respective capacities, models 3 and 4 were long dry kilns with 25 and 40 ton/hour

respective capacities, models 5 and 6 were preheater kilns with 40 and 70 ton/hour respective

capacities, and models 7 and 8 were precalciner kilns with 100 and 150 ton/hour respective

capacities. The results of the cost analysis in 1997 dollars are summarized in Chapter 6.

9

1. U.S. Environmental Protection Agency. Alternative Control Techniques Document - NOX

Emissions from Cement Manufacturing. EPA-453/R-94-004. Research Triangle Park,

NC. March 1994.

2. U.S. Environmental Protection Agency. Compilation of Air Pollutant Emission Factors.

AP-42. Fifth Edition. Volume I - Stationary Point and Area Sources. Research Triangle

Park, NC. January 1995. pp. 11.6-1 - 11.6-26.

Cost effectiveness was also estimated for each technology. A summary of the results is

presented in Table 2-3. Greater detail on the cost analysis and cost effectiveness estimates is

presented in Chapter 6.

TABLE 2-3. SUMMARY OF COST EFFECTIVENESS

(1997 Dollars/ton NOX Reduced)

Technology Range of Annual

Cost Effectiveness

Average Annual

Cost Effectiveness

Average Ozone

Season Cost

Effectiveness

CemStar n/a 550 1,100

Low-NOX

Burners

Indirect-

Fired Kilns

300 to 620 440 1,060

Direct-Fired

Kilns

760 to 1200 940 2,260

Mid-Kiln Firing (460) to 730 55 130

Tire Derived Fuel at a

Precalcinera

(1,900)b (1,900)b (4,500)b

Biosolids Injection n/a (310)b (740)b

NOXOUT® 1,000 to 2,500 1,750 2,160

N/A - not applicable

( ) - indicates a negative costa The purchased equipment and total capital investment costs for a tire derived fuel installation

on a precalciner are very similar to mid-kiln firing.b Represents a single installation.

2.4 REFERENCES

10

3. Memo from Battye, R., and S. Walsh, EC/R Incorporated, Chapel Hill, NC to D. Sanders,

U.S. EPA, RTP, NC. Derivation and data supporting development of cement plant NOX

emission rates. September 5, 2000.

4. Strietman, F.L, T.B. Carter, and G.J. Hawkins. Regulation and Control of NOX Emission

from the Portland Cement Industry. Presented at the 1999 IEEE Gulf Coast Cement

Industry Conference. Charleston, SC. September 30 and October 1, 1999.

5. Portland Cement Association. U.S. and Canadian Portland Cement Industry: Plant

Information Summary. Skokie, IL. December 31, 1998. 214 pp.

6. Helmuth, R.A., F.M. Miller, T.R. O'Connor, and N.R. Greening. Kirk-Othmer

Encyclopedia of Chemical Technology. Vol. 5. Third Edition. New York, NY. John

Wiley & Sons, Inc. 1979. pp. 163-193.

7. Yee, G.M. Suggested Control Measure for the Control of Emissions of Oxides of

Nitrogen from Cement Kilns. Presented to the State of California, Air Resources Board

for Discussion on October 21, 1981.

8. Miller, F.M. Oxides of Nitrogen. GTC Presentation, Kansas City, MO, September 20,

1977.

9. Hansen, E.R., “The Use of Carbon Monoxide and Other Gases for Process Control,” 27th

IEEE Cement Industry Technical Conference Proceedings, May 1985.

10. Andover Technology Partners. NOX Reduction from Cement Kilns Using the CemStar

Process, Evaluation of CemStar Technology - Final Report to Texas Industries. Dallas,

Texas. April 18, 2000.

11. Thomsen, K., L.S. Jensen, and F. Schomburg. FLS-Fuller ILC-lowNOx calciner

commissioning and operation at Lone Star St. Cruz in California. ZKG International.

October 1998. pp. 542 - 550.

12. Steinbiß, V.E., C. Bauer, and W. Breidenstein. Current state of development of the

PYRO-JET® burner. VDZ Kongress. 1993.

13. Letter and attachments from M.H. Vaccaro, Pillard Combustion Equipment and Control

Systems, to G.J. Hawkins, Portland Cement Association, re: Low NOX Rotaflam®

burner, dated January 20, 1999.

14. PSM International, “Response to USEPA Comments, 13 September 1995, on the

proposed alternative NOX RACT for a portland cement manufacturing plant located in

Thomaston, Maine and owned by Dragon Products Company,” Jan 31, 1996.

11

15. Renfrew, S, Process Engineer, RMC Lonestar. Calciner modification highly effective in

meeting Northern California Plant’s alkali reduction and emission control requirements.

no date.

16. Email transmission from Hawkins, G., PCA, Skokie, IL to B. Neuffer, U.S. EPA. Results

of PCA Survey - Preliminary NOX Control Technology Questionnaire. January 2000.

17. Letter from R. Battye and S. Edgerton, EC/R Incorporated, Chapel Hill, NC, to B.

Neuffer, USEPA, RTP, NC. Summary of February 4, 2000 conference call on PCA

Survey - Preliminary NOX Control Technology Questionnaire. February 11, 2000.

18. Walquist, C., Cadence Environmental Energy. “Cadence system leads to fall in NOX

emissions,” World Cement, Dec 1997, pp. 26, 27.

19. Cadence Environmental Energy and Ash Grove Cement. “Mid-Kiln Fuel Entry

Benefits,” section 3 of the report, Emission, Reduction, Technology: Resource

Conservation & Recovery. (no date).

20. Letter from Edgerton, S. and T. Stobert, EC/R Inc., to Bill Neuffer, EPA, Feb 8, 2000.

Minutes from Dec 16, 1999 meeting with representatives from EPA and Cadence.

21. Texas Natural Resources Conservation Commission. A list of permitted NOX levels for

cement plants in the state, CEMS data as reported by the facilities for 1994 - 1999, and

information on the control technology in use at each facility.

22. May, M. and L. Walters, Jr. "Low NOX & Tire-derived Fuel for the Reduction of NOX

from the Portland Cement Manufacturing Process." Cement Americas, August 1999, pp.

10-1.

23. Letter and attachments from Bramble, Kim, Cadence, to Bill Neuffer, USEPA, re: NOX

Emission Reducing Technology, dated Feb 14, 2000.

24. Radian Corporation, "MDE Air Permit Test Report for Lehigh Portland Cement

Company, Union Bridge, Maryland Facility," January 1996.

25. Shumway, D.C. “Tire Derived Fuel at Mitsubishi Cement Corporation.” Received

during December 2, 1999 visit to Mitsubishi.

26. Sun, et. al. Reduction of NOX Emissions from Cement Kiln/ Calciner through the Use of

the NOXOUT Process. Presented at the International Specialty Conference on Waste

Combustion in Boilers and Industrial Furnaces. Kansas City, MO. April 1994.

27. Interoffice Correspondence from McAnany, L. to H. Knopfel, H, LaFarge Corporation.

October 26, 1998. re: Fuel Tech NOXOUT Testing.

12

28. European Commission. Integrated Pollution Prevention and Control (IPPC) Reference

Document on Best Available Techniques in the Cement and Lime Manufacturing

Industries. Joint Research Centre, Institute for Prospective Technological Studies,

Technologies for Sustainable Development, European IPPC Bureau, World Trade Center,

Seville, Spain. March 2000.

29. Battye, R., and S. Edgerton, EC/R Incorporated, Chapel Hill, NC. Trip Report to

Mitsubishi Cement Corporation, Cushenbury Plant, Lucerne Valley, CA, December 2,

1999. Prepared for the U.S. EPA, RTP, NC, under contract No. 68-D-98-026, work

assignment No. 2-28. July 5, 2000.

30. Biggs, H.O., Plant Manager, Mitsubishi Cement Corporation. Biosolids Injection

Technology: An Innovation in Cement Kiln NOX Control. (no date). Received during

December 1999 trip report.

13

3.0 INDUSTRY DESCRIPTION

3.1 BACKGROUND

This chapter provides an overview of the cement industry, its annual production rates, and

the various manufacturing processes used. Process and operating parameters most influential for

NOX formation in the various processes are discussed.

The cement industry is a vital industry for a modern society because cement is an

essential ingredient in concrete. One need only mention reinforced-concrete walls and girders,

tunnels, dams, and roads to realize the dependence of our society upon cement products.

Hydraulic portland cement, the primary product of the cement industry, is made from clinker

blended with gypsum. Clinker is produced by heating a mixture of limestone, clay, and other

ingredients to incipient fusion at a high temperature. Limestone is the single largest ingredient

required in the cement-making process, and most cement plants are located near large limestone

deposits. Portland cement is used in almost all construction applications including homes, public

buildings, roads, industrial plants, dams, bridges, and many other structures.

In the cement-making process, the solid raw materials are heated to their fusion

temperature, typically 1400 to 1500 C (2550 to 2750 F), by burning various fuels such as coal.

Portland cement has been defined as “a hydraulic cement produced by pulverizing portland-

cement clinker and usually containing calcium sulfate.”1 Portland-cement clinker has been

defined as “a clinker, partially fused by pyroprocessing, consisting predominantly of crystalline

hydraulic calcium silicates.”1 Burning an appropriately proportioned mixture of raw materials at

a suitable temperature produces hard fused nodules called clinker which are further ground to a

desired fineness. Five types of portland cement are recognized in the United States which

contain varying amounts of the basic clinker compounds given in Table 3-1.2 Different types of

cements are produced by starting with appropriate kiln feed composition, blending the clinker

with the desired amount of calcium sulfate, and grinding the product mixture to appropriate

fineness. Manufacture of cements of all of the various types involves the same basic high

temperature fusion and clinkering process responsible for the NOX emissions from cement kilns.

3.2 TYPES OF CEMENT PRODUCED

The five basic types of portland cement recognized and produced in the United States are

described below.2,3 In addition, different varieties are prepared by using various blending

formulations.4

Type I portland cement is a normal, general-purpose cement suitable for all uses. It is

used in general construction projects such as buildings, bridges, floors, pavements, and other

precast concrete products. Type I is also known as regular cement and most commonly known as

gray cement because of its color. White cement typically contains less ferric oxide and is used

for special applications. There are other types of cements in general use such as oil-well cement,

14

quick-setting cement, and others for special applications. Type IA portland cement is similar to

Type I with the addition of air-entraining properties.

TABLE 3-1. BASIC CLINKER COMPOUNDS2

Formula Name

2CaOSiO2 Dicalcium silicate

3CaOSiO2 Tricalcium silicate

3CaOAL203 Tricalcium aluminate

4Ca0A1203Fe203 Tetracalcium aluminoferrite

Mg0 Magnesium oxide in free state or combined in di- or tri- calcium silicate lattice.

Type II portland cement generates less heat at a slower rate and has a moderate resistance

to sulfate attack. Type II portland cements are for use where moderate heat of hydration is

required or for general concrete construction exposed to moderate sulfate action. Type IIA

portland cement is identical to Type II and produces air-entrained concrete.

Type III portland cement is a high-early-strength cement and causes concrete to set and

gain strength rapidly. Type III is chemically and physically similar to Type I, except that its

particles have been ground finer. It is made from raw materials with a lime to silica ratio higher

than that of Type I cement. They contain a higher proportion of tricalcium silicate (3Ca0Si02)

than regular portland cements. Type IIIA is an air-entraining, high-early-strength cement.

Type IV portland cement has a low heat of hydration and develops strength at a slower

rate than other cement types, making it ideal for use in dams and other massive concrete

structures where there is little chance for heat to escape. Type IV portland cement contains a

lower percentage of tricalcium silicate (3Ca0Si02) and tricalcium aluminate (3Ca0A1203) than

type I, thus lowering the heat evolution. Consequently, the percentage of dicalcium silicate is

increased substantially and the percentage of tetracalcium aluminoferrite (4Ca0A1203Fe203) may

be increased or may stay the same.

Type V portland cement is used only in concrete structure that will be exposed to severe

sulfate action, principally where concrete is exposed to soil and groundwater with a high sulfate

content. Type V portland cement are those which, by their composition or processing, resist

sulfates better than the other four types.

The use of air-entraining agents increases the resistance of the hardened concrete to

scaling from alternate freezing and thawing. By adding these materials to the first three types of

cements, IA, IIA, and IIIA varieties of cements are produced. Additional varieties of cements are

produced for special applications by blending different ingredients: masonry cement, expansive

cement, oil-well cement, etc. Masonry cements are commonly finely ground mixtures of

15

Figure 3-1. Annual clinker production. 5

portland cement, limestone, and air-entraining agents. Granulated blast furnace slags and natural

or artificial pozzolans are mixed and interground with portland cement to prepare still other

varieties such as blended types IP, IS, S, I(PM), and I(SM).4

3.3 INDUSTRY CHARACTERIZATION

3.3.1 Description of the Cement

Industry

About 77.6 million metric tons of

gray portland and 274,000 metric tons of

white cement were produced in a total of

198 cement kilns at 118 plants in the

United States in 1998.5 This was a 6.0

percent increase from the 1990 reported

total production of 73.5 million metric

tons. As shown in Figure 3-1, cement

industry annual clinker capacity steadily

declined from the 1975 peak through

1990 and has steadily increased since the

1990 low. While the number of kilns has

dropped off sharply, average kiln size has

increased. Since 1973 when average kiln

size was 173,000 metric tons, average kiln size has now reached 393,000 metric tons. Although

42 cement companies produced clinker in 1998, the top 5 companies provided about 44.2 percent

of the total finish grinding capacity. This is evidence of a high concentration of the U.S.

production among a limited number of top producers. Table 3-2 provides a list of all companies

along with their share of the total clinker production. Table 3-3 lists the clinker producing

capacity in the United States by States. The locations of the operating kilns are shown in

Figure 3-2. California and Texas are the two largest states in terms of clinker capacity with

Pennsylvania, Missouri, and Alabama rounding out the top five. Fourteen states and the District

of Columbia had no cement clinker- producing plants in 1998.5

TABLE 3-2. UNITED STATES CEMENT COMPANY CAPACITIES IN 1998

(INCLUDES GRAY AND WHITE PLANTS) 5

Rank Clinker

(103 tons/year)

Percent

Industry

Company Name

1

2

3

9371

8297

6459

12.0

10.6

8.3

Holnam Inc.

Southdown Inc.

Lafarge Corporation

TABLE 3-2. UNITED STATES CEMENT COMPANY CAPACITIES IN 1998 (continued)

(INCLUDES GRAY AND WHITE PLANTS) 5

Rank Clinker

(103 tons/year)

Percent

Industry

Company Name

16

4

5

6

4738

4367

3972

6.1

5.6

5.1

Ash Grove Cement Company

Blue Circle Inc.

Essroc Cement Corporation

7

8

9

3374

3119

3096

4.3

4.0

4.0

Lone Star Industries

Lehigh Portland Cement

Texas Industries

10

11

12

2965

2711

1616

3.8

3.5

2.1

California Portland Cement

RC Cement Company, Inc.

Centex

13

14

15

1580

1457

1387

2.0

1.9

1.8

Mitsubishi Cement Corporation

Kaiser Cement Corporation

Calaveras Cement Company

16

17

18

1358

1075

1047

1.7

1.4

1.3

Giant Cement Holding, Inc.

Kosmos Cement Company

St. Lawrence Cement Company

19

20

21

1003

1003

952

1.3

1.3

1.2

Texas-Lehigh Cement Company

Roanoke Cement Company

National Cement Company of Alabama

22

23

24

870

868

866

1.1

1.1

1.1

Sunbelt Cement Corporation

Capitol Cement Corporation

Pennsuco Cement Company

25

26

27

840

812

788

1.1

1.0

1.0

Allentown Cement Company Inc.

Dacotah Cement

Alamo Cement Company

28

29

30

768

763

755

1.0

1.0

1.0

North Texas Cement

Capitol Aggregates, Inc.

RMC Lonestar

31

32

33

639

567

562

0.8

0.7

0.7

Monarch Cement Company

Phoenix Cement Company

National Cement Company of California

TABLE 3-2. UNITED STATES CEMENT COMPANY CAPACITIES IN 1998 (continued)

(INCLUDES GRAY AND WHITE PLANTS) 5

Rank Clinker

(103 tons/year)

Percent

Industry

Company Name

17

34

35

36

545

545

498

0.7

0.7

0.6

Continental Cement Company, Inc.

Florida Crushed Stone

Dixon-Marquette

37

38

39

494

492

432

0.6

0.6

0.6

Rinker Portland Cement Corporation

Glens Falls Cement Company, Inc.

Rio Grande Cement Corporation

40

41

42

392

294

177

0.5

0.4

0.2

Dragon Products Company

Armstrong Cement & Supply Corporation

Royal Cement Company, Inc.

Total: 77914

TABLE 3-3. UNITED STATES 1998 CLINKER CAPACITIES BY STATE

(INCLUDES GRAY AND WHITE PLANTS) 5

Clinker

(103

tons/year)

No. of

Facilities

Making

Clinker

No. of Kilns States

10461

8187

6809

4497

4233

10

10

10

5

5

18

19

21

7

6

California

Texas

Pennsylvania

Missouri

Alabama

TABLE 3-3. UNITED STATES 1998 CLINKER CAPACITIES BY STATE (continued)

(INCLUDES GRAY AND WHITE PLANTS) 5

Clinker

(103

tons/year)

No. of

Facilities

Making

Clinker

No. of Kilns States

18

4228

3071

2745

2670

2632

3

4

3

4

4

8

7

4

8

8

Michigan

Florida

New York

Illinois

Indiana

2630

2462

1748

1728

1719

3

3

3

2

3

7

4

7

7

7

South Carolina

Iowa

Oklahoma

Arizona

Maryland

1710

1690

1259

1127

1104

4

3

2

2

2

11

5

2

3

3

Kansas

Colorado

Utah

Georgia

Ohio

1060

1044

1003

868

843

2

2

1

1

1

3

2

1

3

1

Tennessee

Washington

Virginia

West Virginia

Nebraska

812

794

759

726

623

1

1

1

1

2

3

3

1

1

3

South Dakota

Arkansas

Oregon

Kentucky

Nevada

TABLE 3-3. UNITED STATES 1998 CLINKER CAPACITIES BY STATE (continued)

(INCLUDES GRAY AND WHITE PLANTS) 5

Clinker

(103

tons/year)

No. of

Facilities

Making

Clinker

No. of Kilns States

19

593

585

433

432

392

2

1

1

1

1

2

2

1

1

1

Montana

Wyoming

Mississippi

New Mexico

Maine

237 1 2 Idaho

77914 105 192

There are no clinker producing plants in the following states:

Alaska Connecticut Delaware

Dist. of Columbia Hawaii Louisiana

Massachusetts Minnesota New Hampshire

New Jersey North Carolina North Dakota

Rhode Island Vermont Wisconsin

20

Figure 3-2. United States and Canadian Portland Cement Locations

(December 31, 1998)

21

The large majority of the cement plants (about 82.4 percent) in the United States are coal

fired with about 2.8 percent using natural gas, and 0.9 percent using oil as the primary fuel.5 The

remaining 13.9 percent of the plants used other combinations, e.g. coal/waste as primary fuel. In

1998, 11 plants used waste as a primary fuel with 49 plants reporting waste as an alternate fuel.

3.3.2 Overview of Cement Manufacturing Process

The process of portland cement manufacture consists of:6

• Quarrying and crushing the rock,

• Grinding the carefully proportioned materials to high fineness,

• Subjecting the raw mix to pyroprocessing in a rotary kiln, and

• Grinding the resulting clinker to a fine powder.

A layout of a typical plant is shown in Figure 3-3 which also illustrates differences

between the two primary types of cement processes: wet process and dry process.6 Newer

designs of dry process plants are equipped with innovations such as precalciners and/or

suspension preheaters to increase the overall energy efficiency of the cement plant.6 Figure 3-4 is

an illustration of a preheater/precalciner type of dry process system.7

The choice between the wet or dry process for cement manufacturing often depends upon

the moisture content in the raw feed materials mined from quarries. If the moisture content of

the feed materials is already very high (15 to 20 percent), a wet process may be attractive. The

recent trend, however, has been toward the dry process with preheater/precalciner systems. In

1998, about 20.6 million metric tons of clinker were produced by the wet process with 57.4

million metric tons produced by a dry process. Within the dry process category, 14.2 million

metric tons were produced by facilities equipped with a preheater system and 26.1 million metric

tons were produced by facilities equipped with a precalciner system.5

The different steps involved in the cement manufacturing process are described in the

following subsections.

3.3.3 Raw Materials and Kiln Feed Preparation

Calcium carbonate and the oxides of silicon, aluminum, and iron comprise the basic

ingredients of cement raw mix. Because of the large requirement for calcium, the plants are

generally located near the source of the calcareous material. The requisite silica and alumina

may be derived from a clay, shale, or overburden from a limestone quarry. Such materials

usually contain some of the required iron oxide, but many plants need to supplement the iron

with mill scale, pyrite cinders, or iron ore. Silica may be supplemented by adding sand to the

22

Figure 3-3. Steps in the manufacture of portland cement. 7

23

Figure 3-4. Preheater/precalciner cement kiln. 7

24

raw mix, whereas alumina can be furnished by bauxites and alumina-rich flint clays.6 Industrial

byproducts are becoming more widely used as raw materials for cement, e.g., slags contain

carbonate-free lime, as well as substantial levels of silica and alumina. Fly ash from utility

boilers can often be a suitable feed component, since it is already finely divided and provides

silica and alumina.

The bulk of raw materials originates in the plant quarry. A primary jaw or roll crusher is

frequently located within the quarry and reduces the quarried limestone or shale to about 100 mm

top size. A secondary crusher, usually roll or hammer mills, gives a product of about 10 to 25

mm top size. Combination crusher-dryers can utilize exit gases from the kiln or clinker cooler to

dry wet material during crushing. Each of the raw materials is stored separately and proportioned

into the grinding mills separately using weigh feeders or volumetric measurements. Ball mills

are used for both wet and dry processes to grind the material to a fineness such that only 15 to 30

wt% is retained on a 74-m (200 mesh) sieve.

In the wet process the raw materials are ground with about 30 to 40 percent water,

producing a well-homogenized mixture called slurry. Raw material for dry process plants is

ground in closed-circuit ball mills with air separators, which may be adjusted for the desired

fineness. Drying may be carried out in separate units, but most often is accomplished in the raw

mill simultaneously with grinding. Waste heat can be utilized directly in the mill by coupling the

raw mill to the kiln or clinker cooler exhaust. For suspension preheater-type kilns, a roller mill

utilizes the exit gas from the preheater to dry the material in suspension in the mill. A blending

system provides the kiln with a homogeneous raw feed. In the wet process the mill slurry is

blended in a series of continuously agitated tanks in which the composition, usually the calcium-

oxide content, is adjusted as required. These tanks may also serve as kiln feed tanks or the slurry

may be pumped to large kiln feed basins. Dry process blending is usually accomplished in a silo

with compressed air.6

3.3.4 Pyroprocessing

All cement clinker is produced in large rotary kiln systems. The rotary kiln is a refractory

brick-lined cylindrical steel shell [3 to 8 m (10 to 25 ft) dia, 50 to 230 m (150 to 750 ft) long]

equipped with an electrical drive to rotate the kiln on its longitudinal axis at 1 to 3 rpm. It is a

countercurrent heating device slightly inclined to the horizontal so that material fed into the

upper end travels slowly by gravity to be discharged into the clinker cooler at the lower,

discharge end. The burners at the firing end, i.e., the lower or discharge end, produce a current of

hot gases that heats the clinker, and the calcined and raw materials in succession as it passes

upward toward the feed end. Refractory bricks of magnesia, alumina, or chrome-magnesite

combinations line the firing end. In the less heat-intensive midsection of the kiln, bricks of lower

thermal conductivity are often used. Abrasion-resistant bricks or monolithic castable linings are

used at the feed end.6

25

Pyroprocessing may be conveniently divided into four stages, as a function of location

and temperature of the materials in the rotary kiln.8

1. Evaporation of uncombined water from raw materials, as material temperature

increases to 100C (212F);

2. Dehydration, as the material temperature increases from 100C to approximately

430C (800F) to form oxides of silicon, aluminum, and iron;

3. Calcination, during which carbon dioxide (CO2) and CaO are formed from

calcium carbonates, primarily between 900C (1650F) and 982C (1800F); and

4. Reaction, of the oxides in the burning zone of the rotary kiln, to form cement

clinker at temperatures of approximately 1510C (2750F).

The duration and location of these stages in an actual kiln depend upon the type of

process used, e.g., wet or dry, and the use of preheaters and precalciners as discussed in the

following section.

It is desirable to cool the clinker rapidly as it leaves the burning zone. Heat recovery,

preheating of combustion air, and fast clinker cooling are achieved by clinker coolers of the

reciprocating-grate, planetary, rotary, or shaft type. Most commonly used are grate coolers where

the clinker is conveyed along the grate and subjected to cooling by ambient air, which passes

through the clinker bed in cross-current heat exchange. The air is moved by a series of

undergrate fans and becomes preheated to 370 to 800 C (700 to 1500 F) at the hot end of

cooler. A portion of the heated air serves as secondary combustion air in the kiln. Primary air is

that portion of the combustion air needed to carry the fuel into the kiln and disperse the fuel.6

3.3.4.1 Wet Process Kilns. In a long wet-process kiln, the slurry introduced into the feed

end first undergoes simultaneous heating and drying. The refractory lining is alternately heated

by the gases when exposed and cooled by the slurry when immersed; thus, the lining serves to

transfer heat as do the gases themselves. Large quantities of water must evaporated, thus most

wet kilns are equipped with chains suspended across the cross section of the kiln to maximize

heat transfer from the gases to the slurry. After most of the moisture has been evaporated, the

nodules, which still contain combined water, move down the kiln and are gradually heated to

about 550 C (1022F) where the calcination reactions commence. The calcined material further

undergoes clinkering reactions. As the charge leaves the burning zone and begins to cool, clinker

minerals crystallize from the melt, and the liquid phase solidifies. The granular clinker material

drops into the clinker cooler for further cooling by air.6

Wet kilns typically represent an older cement technology with smaller capacity kilns. In

the United States wet cement kiln capacities range from 77,000 to 1,179,000 metric tons/year

with an average of 307,000 metric tons/year.5

26

3.3.4.2 Dry Process Kilns. The dry process utilizes a dry kiln feed rather than a slurry.

Early dry process kilns were short, and the substantial quantities of waste heat in the exit gases

from such kilns were frequently used in boilers to generate electric power which often satisfied

all electrical needs of the plant. In one modification, the kiln has been lengthened to nearly the

length of wet-process kilns and chains were added. The chains serve almost exclusively a heat-

exchange function. Refractory heat -recuperative devices, such as crosses, lifters, and trefoils,

have also been installed. So equipped, the long dry kiln is capable of better energy efficiency

than wet kilns. Other than the need for evaporation of water, its operation is similar to that of a

wet kiln. To improve the energy efficiency of the dry process, variations such as suspension

preheaters and precalciners have been introduced as discussed in the next sections.6

Long dry process kilns are generally of a smaller capacity compared to long wet kilns. In

the United States dry cement kiln capacities range from 50,000 to 590,000 metric tons/year with

an average capacity of 265,000 metric tons/year.5

3.3.4.3 Suspension Preheaters. In systems with suspension preheaters, the dry,

pulverized feed passes by gravity through a series of cyclones in a vertical arrangement where it

is separated and preheated several times, typically in a four-stage cyclone system. The partially

(40 to 50 percent) calcined feed exits the preheater tower into the kiln at about 800 to 900 C

(1500 to 1650 F). The kiln length required for completion of the cement formation is

considerably shorter than that of conventional kilns, and heat exchange is very good. Suspension

preheater kilns are very energy efficient compared to wet or long dry kilns. The intimate mixing

of the hot gases and feed in the preheaters promotes condensation of alkalies and sulfur on the

feed which sometimes results in objectionable high alkali and sulfur contents in the clinker. To

alleviate this problem, some of the kiln exit gases can bypass the preheater through a slip stream

or fewer cyclone stages can be used in the preheater with some sacrifice of efficiency.6

Suspension preheater kilns represent a newer cement technology compared to the long

dry kilns. They are also somewhat larger in production capacity than the long conventional

rotary kilns. In the United States the preheater type kiln capacities range from 223,000 to

1,237,000 metric tons/year with an average capacity of 406,000 metric tons/year.5

3.3.4.4 Precalciner Systems. The success of preheater kiln systems, led to precalciner

kiln systems. These units utilize a second burner to carry out calcination in a separate vessel

attached to the preheater. The calciner utilizes preheated combustion air drawn from the clinker

cooler or kiln exit gases and is equipped with a burner that burns about 60 percent of the total

kiln fuel. Most often coal is used as a fuel in a calciner furnace; however, almost any fuel may

be used including chipped tires. The raw material is calcined almost 95 percent, and the gases

continue their upward movement through successive cyclone preheater stages in the same

manner as in an ordinary preheater. The precalciner system permits the use of smaller dimension

kilns since only actual clinkering is carried out in the rotary kiln. Energy efficiency is even better

than that of a preheater kiln, and the energy penalty for bypass of kiln exit gases is reduced since

27

only about 40 percent of the fuel is being burned in the kiln. The burning process and the clinker

cooling operations for the modern dry-process kilns are the same as for long wet kilns.6

The precalciner technology is the most modern cement manufacturing technology and

almost all of the newer cement plants are based on these designs. Precalciner kilns are also much

larger in capacity than the conventional rotary kilns. The precalciner type kilns in the United

States range from 449,000 to 1,580,000 metric tons/year with an average of 869,000 metric

tons/year.5 Because of the new large precalciner plants replacing older and smaller plants, the

overall average kiln capacity has been steadily increasing in the United States. It has increased

from an average of 239,000 metric tons/year in 1980 to an average capacity of 393,000 metric

tons/year in 1989.5

3.3.5 Finish Grinding

The cooled clinker is conveyed to clinker storage. It is subsequently mixed with 4 to 6

percent gypsum and introduced directly into the finish mills. These are large, steel cylinders [2

to 5 m (7 to 16 ft) in diameter] containing a charge of steel balls, that rotate at about 15 to 20

rpm. The clinker and gypsum are ground to a fine, homogeneous powder. About 85 to 96

percent of the product is in particles less than 44 m in diameter. This grinding may be

accomplished by two different mill systems. In open-circuit milling, the material passes directly

through the mill without any separation. A wide particle size distribution range is usually

obtained with substantial amounts of very fine and rather coarse particles. Open circuit grinding

is, however, rarely practiced in U.S. cement plants. In closed-circuit grinding, the mill product is

carried to a cyclonic air separator in which the coarse particles are rejected from the product and

returned to the mill for further grinding.6

3.3.6 Quality Control

Beginning at the quarry operation, quality of the end product is maintained by

adjustments of composition, burning conditions, and finish grinding. Control checks are made

for fineness of materials, chemical composition, and uniformity. Clinker burning is monitored

by the liter weight test weighing a portion of sized clinker, a free lime test, or checked by

microscopic evaluation of the crystalline structure of the clinker compounds. Samples may be