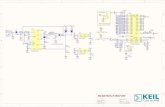

Toshiba Satellite A135-S2686 Compal LA-3391P Laptop Schematics

TOSHIBA...equipment schedules, drawings, schematics etc) attached, utilising Toshiba 2-Pipe Super...

Transcript of TOSHIBA...equipment schedules, drawings, schematics etc) attached, utilising Toshiba 2-Pipe Super...

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Introduction The following specification describes the Toshiba 2-Pipe Heat pump Super Modular Multi System ‘I’ (SMMSi) air conditioning system(s) to be installed at the below site: (ADD SITE NAME) The system(s) shall consist of the following components. It shall be the responsibility of the nominated installer to supply and install these system components in accordance with Toshiba Installation Guidelines. 1) Toshiba Super Modular Multi external air cooled condensing unit(s) 2) Toshiba Super Modular Multi compatible type indoor units 3) Interconnecting U1 & U2 control wiring from Outdoor Unit(s) to Indoor Units 4) Interconnecting U5 & U6 control wiring between Outdoor Units (if required) 5) Toshiba TCC Link Integrated Controls 6) Interconnecting refrigerant pipework from Outdoor Units to Indoor Units using Toshiba

Y-Branch Kits/Header Kits/Tee-Piece Kits. System Operating Range

Mode of operation Cooling Heating Max. Outdoor Air Temperature 0C db 43 21 Min. Outdoor Air Temperature 0C db -5 -15 Max. Indoor Air Temperature 0C db - 29 0C wb 28 - Min. Indoor Air Temperature 0C db - 4 0C wb 15 - Maximum indoor Humidity % RH 80 System Description

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The installation shall provide an energy efficient R410A Variable Refrigerant Flow (VRF) comfort air conditioning system(s) to the designated area(s)/Zone(s) as per the (insert either equipment schedules, drawings, schematics etc) attached, utilising Toshiba 2-Pipe Super Modular Multi system(s) and shall be installed in accordance with relevant codes of practice and regulations. The system(s) shall comprise of Toshiba 2-Pipe Heatpump Super Modular Multi outdoor units connected to indoor fan coil units, via the most appropriate and cost efficient combination of Y-Branch Kits/Header Kits/Tee-Piece Kits. The system(s) shall be controlled with Toshiba’s TCC-Link controls system selected in accordance with the specific control requirements detailed below: (Insert controls requirements) The total refrigerant pipework circuit can be a maximum linear distance of 150m between the outdoor and the furthest heat pump indoor unit and incorporate a height difference of: - 50m - indoor unit below outdoor unit 40m - indoor unit above outdoor unit The maximum elevation between the highest and lowest indoor units shall not exceed 30m, in accordance with Toshiba Installation Guidelines. It shall not be necessary to include oil traps, sight glasses, or external driers in any of the pipework. It is recommended that the air conditioning installing contractor is a Refcom Certified Toshiba Additions Member. Full details on our website: www.toshiba-aircon.co.uk. Customer Support. DELETE WARRANTIES THAT DO NOT APPLY All equipment supplied shall have a manufacturer’s warranty of at least 3-years on all parts and labour in accordance with Toshiba’s warranty and installation guidelines. Equipment to be installed by a Toshiba “Registered” installer or “Qualified or Accredited” All equipment supplied shall have a manufacturer’s warranty of 5-years on all parts and labour in accordance with Toshiba’s warranty and installation guidelines. Equipment to be installed by a Toshiba Qualified or Accredited installer. All equipment supplied shall have a manufacturer’s 7 year “Total Peace of Mind” (TPM) warranty on all parts and labour in accordance with Toshiba’s warranty and installation guidelines. Equipment to be installed by a Toshiba Accredited (TPM) installer. Design Criteria

The air conditioning system(s) shall be designed and equipment selected to conform to the following design criteria:

Internal Conditions Summer 23°C db, 50% RH Winter 22°C db

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

External Conditions Summer 30°C db, 21.5°C wb Winter -3°C db System Specification

The system(s) shall be VRF 2-Pipe Heatpump Super Modular Multi and multiple indoor units to provide heating & cooling. The system will use non-ozone depleting HFC refrigerant R410A and be able to run with a minimum indoor cooling demand of 2.2 kW. The air conditioning system must automatically adapt to the number of fan coil units turned on by the room tenants. The system shall allow a user-driven operating environment to be established where users can directly request their own choice of temperature and on/off control etc. The equipment must be suitable for operating on a 220-240 volt, single-phase, 50Hz supply for indoor units and a 380-415 volt, three-phase, 50Hz supply for the outdoor units. Outdoor Unit(s) Toshiba Model References: - Standard Combinations SMMSi - MMY-MAP0804HT8P-E, MMY-MAP1004HT8P-E, MMY-MAP1204HT8P-E, MMY-MAP1404HT8P-E, MMY-MAP1604HT8P-E Outdoor Unit(s) Outdoor Unit(s)

Hp kW No. Of Outdoor Modules

No. Of Inverter Compressors

MMY-MAP0804HT8P-E 08 22.4 1 2 MMY-MAP1004HT8P-E 10 28.0 1 2 MMY-MAP1204HT8P-E 12 33.5 1 3 MMY-MAP1404HT8P-E 14 40.0 1 3 MMY-MAP1604HT8P-E 16 45.0 1 3 MMY-AP1814HT8P-E 18 50.4 2 (10+8) 4 MMY-AP2014HT8P-E 20 56.0 2 (10+10) 4 MMY-AP2214HT8P-E 22 61.5 2 (12+10) 5 MMY-AP2414HT8P-E 24 68.0 2 (12+12) 6 MMY-AP2614HT8P-E 26 73.0 2 (16+10) 6 MMY-AP2814HT8P-E 28 78.5 2 (16+12) 6 MMY-AP3014HT8P-E 30 85.0 2 (16+14) 6 MMY-AP3214HT8P-E 32 90.0 2 (16+16) 6 MMY-AP3414HT8P-E 34 96.0 3 (12+12+10) 8 MMY-AP3614HT8P-E 36 101.0 3 (12+12+12) 9 MMY-AP3814HT8P-E 38 106.5 3 (16+12+10) 9

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

MMY-AP4014HT8P-E 40 112.0 3 (16+12+12) 9 MMY-AP4214HT8P-E 42 118 3 (16+14+12) 9 MMY-AP4414HT8P-E 44 123.5 3 (16+14+14) 9 MMY-AP4614HT8P-E 46 130.0 3 (16+16+14) 9 MMY-AP4814HT8P-E 48 135.0 3 (16+16+16) 9

The systems shall have minimum energy efficiency in heating and cooling as detailed below. Outdoor Unit(s)

SEER ESEER SCOP ESCOP

MMY-MAP0804HT8P-E 7.3 7.68 5.84 6.08 MMY-MAP1004HT8P-E 6.65 6.99 5.43 5.65 MMY-MAP1204HT8P-E 6.37 6.71 4.88 5.09 MMY-MAP1404HT8P-E 6.51 6.88 5.18 5.39 MMY-MAP1604HT8P-E 6.39 6.78 4.86 5.09 MMY-AP1814HT8P-E 6.91 7.26 5.59 5.81 MMY-AP2014HT8P-E 6.65 6.99 5.41 5.63 MMY-AP2214HT8P-E 6.48 6.83 5.08 5.29 MMY-AP2414HT8P-E 6.28 6.62 4.79 5.0 MMY-AP2614HT8P-E 6.39 6.75 4.98 5.2 MMY-AP2814HT8P-E 6.35 6.71 4.82 5.03 MMY-AP3014HT8P-E 6.45 6.82 4.98 5.2 MMY-AP3214HT8P-E 6.41 6.79 4.86 5.08 MMY-AP3414HT8P-E 6.37 6.71 4.94 5.15 MMY-AP3614HT8P-E 6.33 6.68 4.84 5.05 MMY-AP3814HT8P-E 6.39 6.74 4.94 5.16 MMY-AP4014HT8P-E 6.35 6.7 4.81 5.02 MMY-AP4214HT8P-E 6.43 6.79 4.93 5.15 MMY-AP4414HT8P-E 6.37 6.74 4.82 5.04 MMY-AP4614HT8P-E 6.43 6.81 5.03 5.26 MMY-AP4814HT8P-E 6.32 6.69 4.86 5.08 Toshiba Model References: - High Efficiency Combinations Outdoor Unit(s) Outdoor Unit(s)

Hp kW No. Of Outdoor Modules

No. Of Inverter Compressors

MMY-AP1624HT8P-E 16 45.0 2(8+8) 4 MMY-AP2424HT8P-E 24 68.0 3(8+8+8) 6 MMY-AP2624HT8P-E 26 73.0 3(10+8+8) 6 MMY-AP2824HT8P-E 28 78.5 3(10+10+8) 6 MMY-AP3024HT8P-E 30 85.0 3(10+10+10) 6 MMY-AP3224HT8P-E 32 90.0 4(8+8+8+8) 8 MMY-AP3424HT8P-E 34 96.0 4(10+8+8+8) 8 MMY-AP3624HT8P-E 36 101.0 4(10+10+8+8) 8 MMY-AP3824HT8P-E 38 106.5 4(10+10+10+8) 8 MMY-AP4024HT8P-E 40 112.0 4(10+10+10+10) 8 MMY-AP4224HT8P-E 42 118 4(12+10+10+10) 9

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

MMY-AP4424HT8P-E 44 123.5 4(12+12+10+10) 9 MMY-AP4624HT8P-E 46 130.0 4(12+12+12+10) 9 MMY-AP4824HT8P-E 48 135.0 4(12+12+12+12) 9

The systems shall have minimum energy efficiency in heating and cooling as detailed below. Outdoor Unit(s)

SEER ESEER SCOP ESCOP

MMY-AP1624HT8P-E 0.64 0.28 5.84 6.07 MMY-AP2424HT8P-E 0.58 0.22 5.75 5.99 MMY-AP2624HT8P-E 0.56 0.21 5.67 5.9 MMY-AP2824HT8P-E 0.54 0.2 5.53 5.75 MMY-AP3024HT8P-E 6.21 6.49 5.4 5.62 MMY-AP3224HT8P-E 0.56 0.2 5.83 6.06 MMY-AP3424HT8P-E 0.54 0.19 5.64 5.87 MMY-AP3624HT8P-E 0.53 0.18 5.6 5.82 MMY-AP3824HT8P-E 0.51 0.17 5.5 5.73 MMY-AP4024HT8P-E 0.5 0.17 5.39 5.61 MMY-AP4224HT8P-E 0.49 0.16 5.24 5.46 MMY-AP4424HT8P-E 0.48 0.16 5.13 5.35 MMY-AP4624HT8P-E 0.47 0.15 4.94 5.15 MMY-AP4824HT8P-E 0.46 0.15 4.86 5.06

Each outdoor unit shall be factory assembled, pre-wired, works tested, supplied with a refrigerant pre-charge and complete with fully sealed pipework connections. The noise level for each unit shall not be more than 59 dB(A) (for a single condenser) and 65 dB(A) (for the maximum combination of four condensers) when measured 1m horizontally and 1m above the base of the unit(s). The access panel shall be easily removable for servicing. The condensing unit shall be fitted with its own electrical compartment with all necessary electrical and control components. An oil management system is to be fitted, to allow oil transfer between connected outdoor units, thereby ensuring that adequate lubrication is provided to every compressor. Provision must be made to facilitate piping connections to the front or bottom of the unit. The unit must consist of an individual compressor/condenser section and condenser fan housed in a sturdy weatherproof casing manufactured from Galvatite steel plate with a Silky shade (Munsell 1Y8.5/0.5) electrostatic spray finish protected to IP X4 and shall contain the following components: Dual & Triple Inverter Driven Twin Rotary Type Compressors These are to be contained in a single housing with, medium pressure liquid, low-pressure gas and oil transport connections and crankcase heater. Each compressor shall be of the twin rotary type, contained in a single housing and driven by a High-Speed Calculation Vector Control Inverter, creating seamless capacity control from 0.8hp upwards to match the connected indoor cooling demand. Fixed speed compressors of any type are not to be used. The compressor shall be mounted on springs and shock-absorbing rubber to minimise vibration. Heat Exchangers Each outdoor unit shall be fitted with a main and a sub heat exchanger. The sub heat exchanger is to increase efficiency by providing further sub-cooling to the refrigerant, when

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

appropriate. The two heat exchangers shall be factory constructed of rifled copper tubing, mechanically bonded to aluminium fins. The aluminium fin material shall be coated with a hydrophilic coating to prevent corrosion and to assist condensate dispersal. Each coil shall have a large surface area to minimize noise and maximise heat transfer. Fan and Motor The fan shall be a three-blade, flash-wing, low noise type and shall be both dynamically and statically balanced to produce minimum noise and vibration. The fan shall be directly coupled and driven by a drip proof, permanently lubricated variable speed high-efficiency inverter controlled motor. The outdoor fan speed shall be matched automatically to the energy demands of the heat exchanger. The fan shall have a factory set external static resistance capability of 15Pa. However, the fan must be able to be boosted by a simple adjustment to the PCB to overcome a resistance of 35Pa with no loss of performance. A maximum external static resistance of 45Pa must be achievable with no more than 3% reduction in performance. Suction Line Accumulator The cylindrical accumulator shall be fabricated from press formed mild steel plates. The accumulator shall have sufficient capacity to prevent any liquid refrigerant from flowing back into the compressor section. The accumulator must be fitted with a heater. Additional Features & Safety Devices 4-way reversing valve; solenoid valves; pulse motor valves; liquid receiver; strainer; dryer; service valves with gauge ports; high and low pressure transducers; high pressure switch, fuses, over current relay; thermal protectors for compressor and fan motor; recycling guard timer; over-current sensor; compressor suction and discharge temperature sensor and a 3-phase and neutral isolator protected to IP65 containing mains power input, terminals, internal wiring and controls. Indoor Units Each indoor unit shall be from Toshiba’s R410A VRF range of units and must operate on 220-240 volt, single-phase, 50Hz supply. It must be fully compatible with all TCC-Link network systems, including a self-diagnostic TCC-Link remote controller or TCC-Link central controller with LCD to set mode, room temperature, timer, louvre (as applicable), fan speed and on/off functions. In the event of a fault, a hexadecimal malfunction code will be displayed. Each indoor unit address is to be automatically set by the system and retained in memory in the event of a power failure. An option to manually set the address must also be available. Electrical isolation of any indoor unit must not affect the operation of the remaining components in the system. An auxiliary 12V DC output is to be available using the CN32 connection. This can be used to operate a ventilation fan via a relay (RBC-SMFI) when the indoor unit is operated. The heat exchanger shall be factory constructed of rifled copper tubing, mechanically bonded to aluminium fins. The aluminium fin material shall be coated with a hydrophilic coating to prevent corrosion and to assist condensate dispersal. The coil shall have a large surface area to minimize noise and maximise heat transfer. An electronic expansion valve shall be factory brazed to the inlet of the coil. It shall modulate the refrigerant volume continuously in response to load variations in the room to maintain a precise constant temperature to within

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

+/-0.5°C. A fully insulated condensate drip tray must be fitted, which spans the full width of the coil connections and complete with a drain connection point. All indoor units are provided with a return air temperature sensor. The heat exchanger will be protected against excessive temperatures both low and high. The evaporator fan shall be of the multi-blade type, performance matched to the coil. The fan shall be statically and dynamically balanced to ensure low noise and vibration free operation and be driven by a permanently lubricated motor fitted with maintenance free sealed-for-life sleeve bearings. 4-Way Cassette Toshiba Model References: MMU-AP0094HP-E, MMU-AP0124HP-E, MMU-AP0154HP-E, MMU-AP0184HP-E, MMU-AP0244HP-E, MMU-AP0274HP-E, MMU-AP0304HP-E, MMU-AP0364HP-E, MMU-AP0484HP-E, MMU-AP0564HP-E The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. Knockouts are to be incorporated into the main chassis of the unit: One to provide a fresh-air intake facility to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space; Three further discharge ports (2 on one side and 1 on the opposite side) are to enable a maximum of 2 spur ducts to be fitted to supply improved air distribution characteristics in irregular shaped rooms or to provide nominal cooling to adjacent areas. An integral condensate lift pump is to be provided with a 640mm lift capability from the drain outlet. The cassette facia panel is to be manufactured from ABS plastic, finished in Moon White (Munsell 2.5GY 9.0/0.5) and complete with four synchronised, motor driven, fully adjustable discharge louvers. The airflow from the unit is to be configurable from the remote controller to compensate for high ceilings. The central return air grille must be fitted with a washable, long life air filter. An optional kit shall be made available (ref: TCB-BC1602UE) incorporating blockers to allow up to two air discharge ports to be closed to create a 2, or 3-way discharge pattern as required. An optional infrared remote control kit (ref: RBC-AX32U(W)-E) is to be available. Compact (600 x 600) 4-Way Cassette Toshiba Model References: MMU-AP0054MH-E, MMU-AP0074MH-E, MMU-AP0094MH-E, MMU-AP0124MH-E, MMU-AP0154MH-E, MMU-AP0184MH-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. Knockouts are to be incorporated into the main chassis of the unit: One to provide a fresh-air intake facility to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space; Two further discharge ports (1 on each side) are to enable a maximum of 2 spur ducts to be fitted to supply improved air distribution characteristics in irregular shaped rooms or to provide nominal cooling to adjacent areas. An integral condensate lift pump is to be provided with a 627 mm lift capability from the drain outlet.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The cassette fascia panel is to be manufactured from ABS plastic, finished in Moon White (Munsell 2.5GY 9.0/0.5) and complete with four synchronised, motor driven, fully adjustable discharge louvres. Each corner of the panel shall be removable to provide access to the drop rods to enable precise height adjustment. The airflow from the unit is to be configurable from the remote controller to compensate for high ceilings. The central return air grille must be fitted with a washable, long life air filter. An optional infrared remote control kit with inclusive temperature sensor (ref: TCB-AX32E2) is to be available. 2-Way Cassette Toshiba Model References: MMU-AP0072WH, MMU-AP0092WH, MMU-AP0122WH, MMU-AP0152WH, MMU-AP0182WH, MMU-AP0242WH, MMU-AP0272WH, MMU-AP0302WH, MMU-AP0362WH, MMU-AP0482WH, MMU-AP0562WH. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. Knockouts are to be incorporated into the main chassis of the unit: One to provide a fresh-air intake facility to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space; two further discharge ports (1 on each side) are to enable a maximum of 2 spur ducts to be fitted to supply improved air distribution characteristics in irregular shaped rooms or to provide nominal cooling to adjacent areas. An integral condensate lift pump is to be provided with a 160mm lift capability from the drain outlet. The cassette facia panel is to be manufactured from ABS plastic, finished in Light Ivory (Munsell 10Y 9/0.5) and complete with two synchronised, motor driven, fully adjustable discharge louvres. The central return air grille must be fitted with a washable, long life air filter. 1-Way Cassette (Y Series) Toshiba Model References: MMU-AP0074YH-E, MMU-AP0094YH-E, MMU-AP0124YH-E, The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. An integral condensate lift pump is to be fitted. The cassette facia panel is to be manufactured from ABS plastic, finished in Silky Shade (Munsell 1Y8.5/0.5) and complete with a single, motor driven, fully adjustable discharge louvre. The return air grille must be fitted with a washable, long life air filter. An optional infrared remote control kit with inclusive temperature sensor (ref: TCB-AX32E2) is to be available. 1-Way Cassette (S Series)

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Toshiba Model References: MMU-AP0154SH-E, MMU-AP0184SH-E, MMU-AP0244SH-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. Knockouts are to be incorporated into the main chassis of the unit: One at the rear to provide a fresh-air intake facility to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space; One at the front to facilitate a ducted discharge capability. An integral condensate lift pump is to be provided. The cassette facia panel is to be manufactured from ABS plastic, finished in Silky Shade (Munsell 1Y8.5/0.5) and complete with a single, motor driven, fully adjustable discharge louvre. The return air grille must be fitted with a washable, long life air filter. An optional infrared remote control kit with inclusive temperature sensor (ref: TCB-AX32E2) is to be available. Standard Ducted Toshiba Model References: MMD-AP0076BHP-E, MMD-AP0096BHP-E, MMD-AP0126BHP-E, MMD-AP0156BHP-E, MMD-AP0186BHP-E, MMD-AP0246BHP-E, MMD-AP0276BHP-E, MMD-AP0306BHP-E, MMD-AP0366BHP-E, MMD-AP0486BHP-E, MMD-AP0566BHP-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. An extra high fan speed setting is to be available, allowing a maximum external static resistance of 100 Pa to be overcome. The airflow from the unit is to be configurable from the remote controller to compensate for high ceilings. Air is to return to the unit at the rear via a washable, long life air filter. A knockout is to be provided to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space. An integral condensate lift pump is to be provided with a 271mm lift capability from the drain outlet. An optional infrared remote control kit (ref: TCB-AX32E2) is to be available. Slim Ducted Toshiba Model References: MMD-AP0054SPH-E, MMD-AP0074SPH-E, MMD-AP0094SPH-E, MMD-AP0124SPH-E, MMD-AP0154SPH-E, MMD-AP0184SPH-E, MMD-AP0244SPH-E, MMD-AP0274SPH-E. The unit must be no more that 210 mm high and manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. The DC fan motor will be configurable, allowing a maximum external static resistance of 50 Pa to be overcome. The airflow from the unit is to be configurable from the remote controller to compensate for high ceilings. Air is to return to the unit at the rear via a washable, long life air filter. A knockout is to be provided to allow up to 10% fresh air (un-tempered) to be introduced into the

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

conditioned space. An integral condensate lift pump is to be provided with a 687 mm lift capability from the drain outlet. An optional infrared remote control kit (ref: TCB-AX32E2) is to be available. High Static Ducted Toshiba Model References: MMD-AP0184H-E, MMD-AP0244H-E, MMD-AP0274H-E, MMD-AP0364H-E, MMD-AP0484H-E, MMD-AP0724H-E, MMD-AP0964H-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam. Each unit is to allow a maximum external static resistance of 196 Pa to be overcome. Air is to return to the unit at the rear. Ceiling Suspended Toshiba Model References: MMC-AP0157HP-E, MMC-AP0187HP-E, MMC-AP0247HP-E, MMC-AP0277HP-E, MMC-AP0367HP-E, MMC-AP0487HP-E, MMC-AP0567HP-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam and encased in an ABS plastic shell, finished in White (Munsell 10Y 9.3/0.4). A front mounted, motor driven, fully adjustable louvre is to be fitted to allow air to be discharged horizontally for maximum cooling. Primary, manually set louvres are to be incorporated to assist the air spread given by the motorised louvre. Return air is to flow through washable, long life air filters mounted within the intake grilles on the underside of the unit. A rear knockout is to be incorporated into the main chassis of the unit to allow up to 10% fresh air (un-tempered) to be introduced into the conditioned space. An optional infrared remote control kit (ref: RBC-AX33E2) is to be available. High-Wall Toshiba Model References: MMK-AP0073H, MMK-AP0093H, MMK-AP0123H, MMK-AP0153H, MMK-AP0183H, MMK-AP0243H. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam and encased in an ABS plastic shell, finished in Silky Mist (Munsell IY8.9/0.5). A lower front mounted, motor driven, fully adjustable louvre is to be fitted. Primary, manually set louvres are to be incorporated to assist the air spread given by the motorised louvre. Return air is to flow through washable, long life air filters mounted within the intake grilles on the upper front of the unit.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Compact High-Wall Toshiba Model References: MMK-AP0074MH-E, MMK-AP0094MH-E, MMK-AP0124MH-E The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam and encased in an ABS plastic shell, finished in Moon White. A lower front mounted, motor driven, fully adjustable louvre is to be fitted. Primary, manually set louvres are to be incorporated to assist the air spread given by the motorised louvre. Return air is to flow through washable, long life air filters mounted within the intake grilles on the upper front of the unit. Chassis Toshiba Model References: MML-AP0074BH-E, MML-AP0094BH-E, MML-AP0124BH-E, MML-AP0154BH-E, MML-AP0184BH-E, MML-AP0244BH-E. The unit will be manufactured from galvanised steel sheet, insulated with closed cell expanded polyurethane foam and be suitable for concealing behind a facia. It must be complete with a removable flange plate to allow the option of either top, or front discharge. Return air is to flow through washable, long life air filters mounted on the underside of the unit. Floor Standing Toshiba Model References: MML-AP0074NH-E, MML-AP0094NH-E, MML-AP0124NH-E, MML-AP0154NH-E, MML-AP0184NH-E. The unit will be manufactured from galvanised steel sheet and finished in Silky Shade (Munsell IY8.5/0.5). A removable discharge grille is to be fitted to allow the option of either top, or front discharge. Return air is to flow through washable, long life air filters mounted within the intake grilles on the lower front of the unit. Cabinet Toshiba Model References: MMF-AP0156H-E, MMF-AP0186H-E, MMF-AP0246H-E, MMF-AP0276H-E, MMF-AP0366H-E, MMF-AP0486H-E, MMF-AP0566H-E The unit will be manufactured from galvanised steel sheet and finished in Silky Shade (Munsell IY8.5/0.5). Supply air is to be discharged forward at the top of the unit through motorised louvres. Return air is to flow through washable, long life air filters mounted within the intake grilles on the lower front of the unit.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Refrigerant Pipework All pipework shall be manufactured using de-oxidised, refrigerant quality copper to BS EN 1057:1996, and must be heat-treated as follows: 6.4mm (1/4”) OD to 15.9mm (5/8”) OD - Soft, Half Hard or Hard Tempered 19.1mm (3/4”) OD to 41.3mm (1 5/8”) OD - Half Hard or Hard Tempered When 15/8” tube is used, it must be 16 gauge. The length/height difference parameters and outside diameter of all piping is to be in accordance with the appropriate Toshiba manuals. All pipework will be purged with oxygen-free nitrogen when brazing and capped at all other times. The system will be leak tested with oxygen-free nitrogen at a pressure of between 490 and 540 psig for a period of at least 8 hours. The oil balance pipe (if used) will be pressurised separately. The system will be de-hydrated by creating a vacuum deeper than 4 Torr – before the vacuum pump is isolated for a period of no less than 30 minutes. If the vacuum falls during this time, oxygen free nitrogen will be added and the dehydration process repeated until the vacuum is maintained for 30 minutes. Virgin refrigerant (R410A) will be added in liquid form in accordance with Toshiba’s requirements. All interconnecting refrigerant pipework from Outdoor Units to Indoor Units is to utilise Toshiba joint kits to create the most practical refrigerant piping network. The range consists of: Y Connector Kit Toshiba Model Reference: RBM-BT14E RBM-BT24E This kit is to be used when two, or more condensers are to be connected together. It shall consist of components to create tee-pieces for the gas pipe, liquid pipe and oil balance pipe for all possible pipe sizes required for Super Modular Multi outdoor units. Y-Branch Kits Toshiba Model References: RBM-BY55E RBM-BY105E RBM-BY205E RBM-BY305E

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

These kits are to consist of a gas pipe branch, liquid pipe branch and related pre-formed thermal insulation pieces. The branch pieces are to come complete with sockets of varying dimensions to accommodate all potential sizes of refrigerant pipe. Header Branching Kits Toshiba Model References: RBM-HY1043E RBM-HY2043E RBM-HY1083E RBM-HY2083E These kits are to consist of a gas pipe branch header (with four, or eight inlets/outlets), liquid pipe branch header (with four, or eight outlets/inlets) and related pre-formed thermal insulation pieces. The header pieces are to come complete with sockets of varying dimensions to accommodate all potential sizes of refrigerant pipe. Interconnecting Controls Wiring The nominated installer shall be responsible for the following interconnecting controls wiring: 2-core, non-polar = Indoor units to Remote Controller (A, B) 2-core, twisted, screened, non-polar = Local Area Network (U1, U2, U5, U6) 2-core, twisted, screened, non-polar = External Controls Network (U3, U4 and/or X, Y) All electrical wiring, bonding and earthing shall be in accordance with the current edition of BS7671: 2008. The single and three phase voltages stated are EC harmonised voltages, but the equipment shall be suitable for 200-240 volts single phase and 380-415 volts three phase as appropriate. Controls The 3-Pipe VRF Super Heat Recovery Multi system(s) shall be complete with the following TCC-Link controls. Simplified TCC-Link Remote Controller Toshiba Model References: RBC-AS41E The remote controller(s) shall be surface mounted and hard wired to the indoor unit(s) via the AB connections, to provide the user with either local individual control of the air-conditioned space. The controller shall be manufactured in ABS plastic with a liquid crystal display (LCD). A temperature sensor is to be incorporated within the casing to allow the user to set the sensing point at the controller, or at the indoor unit. The controller shall display an alphanumeric fault code in the event of system malfunction. The controller shall provide control of the following primary functions:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C).

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

0.5 degree set point change Fan speed (high, medium, low & auto). Louver position (where applicable). Filter check. Test run (heating & cooling). Screw type terminal

Standard TCC-Link Remote Controller Toshiba Model References: RBC-AMT32E The remote controller(s) shall be surface mounted and hard wired to the indoor unit(s) via the AB connections, to provide the user with either local individual control of the air-conditioned space, or group control of up to 8 indoor units. The controller shall be manufactured in ABS plastic with a liquid crystal display (LCD). A temperature sensor is to be incorporated within the casing to allow the user to set the sensing point at the controller, or at the indoor unit. The controller shall enable the user to interrogate the system and display an alphanumeric fault code in the event of system malfunction. The controller shall be able to provide control or indicate status of the following functions:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). Fan speed (high, medium, low & auto). Louver position (where applicable). Individual Louvre Control (where applicable). Filter check. Test run (heating & cooling). Minimum and maximum temperature settings in each mode Dead band between heating and cooling. Stratification control. Central control address. Auto-restart. Temperature sensor in use. High ceiling compensation. Elapsed timer lock. Sensor data available from all associated indoor and outdoor units Integral elapsed timer

Standard TCC-Link Remote Controller with 24 Hour, Seven Day Timer Toshiba Model References: RBC-AMS41E The remote controller(s) shall be surface mounted and hard wired to the indoor unit(s) via the AB connections, to provide the user with either local individual control of the air-conditioned space, or group control of up to 8 indoor units. The controller shall be manufactured in ABS plastic with a liquid crystal display (LCD). A temperature sensor is to be incorporated within the casing to allow the user to set the sensing point at the controller, or at the indoor unit. The

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

controller shall enable the user to interrogate the system and display an alphanumeric fault code in the event of system malfunction. The controller shall be able to provide control or indicate status of the following functions:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). Fan speed (high, medium, low & auto). Louver position (where applicable). Individual Louvre Control (where applicable). Filter check. Test run (heating & cooling). Minimum and maximum temperature settings in each mode Dead band between heating and cooling. Stratification control. Central control address. Auto-restart. Temperature sensor in use. High ceiling compensation. Elapsed timer lock. Sensor data available from all associated indoor and outdoor units Integral 24 Hour, Seven Day Timer.

The Lite–Vision Plus Remote Controller Toshiba Model References: RBC-AMS51E-ES The remote controller(s) shall be surface mounted and hard wired to the indoor unit(s) via the AB connections, to provide the user with either local individual control of the air-conditioned space, or group control of up to 8 indoor units. The controller shall be manufactured in ABS plastic with a new liquid crystal display (LCD) with backlight. A temperature sensor is to be incorporated within the casing to allow the user to set the sensing point at the controller, or at the indoor unit. The controller shall enable the user to interrogate the system and display an alphanumeric fault code in the event of system malfunction. The controller shall be able to provide control or indicate status of the following functions:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). – Increments of 0.5°C. Fan speed (high, medium, low & auto). Louvre position (where applicable). Filter check. Test run (heating & cooling). Save mode (dependant on model & system) Schedule 7 day timer operation (Operation time, start/stop, temp setting &

restriction) Timer operation (Countdown timer) Minimum and maximum temperature settings in each mode Dead band between heating and cooling. Stratification control.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Central control address. Auto-restart. Temperature sensor in use. High ceiling compensation. Elapsed timer lock. Sensor data available from all associated indoor and outdoor units Unique Energy Saver Function Menu based operational strategy Weekly timer function with multi – programmable settings Fully compatible with Toshiba DI / SDI and VRF systems Programmable button restrictions Individual registering of the room name Illuminated display Option to display service providers name and telephone number Full ventilation options when used in conjunction with Toshiba’s new VN-M air to

air heat exchanger unit(s) Built in backup power settings. Settings kept in memory up to 48 hours in case of

power failure. Wireless Infra-red Controller Toshiba Model References: TCB-AX32E2 – Receiver kit for wall and ceiling units RBC-AX33CE – VRF ceiling models and VRF one-way cassette RBC-AX32U(W)-E – DI/S-DI and VRF 4-way standard cassette RBC-AX32UW(W)-E – VRF two way cassette The remote controller(s) can be placed anywhere in the room where the units is located. The receiver unit is hard wired to the indoor unit(s) via the AB connections. The controller shall be manufactured in ABS plastic with a new liquid crystal display (LCD). The controller shall enable the user to provide control or indicate status of the following functions:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). Fan speed (high, medium, low & auto). Louvre position (where applicable). Fault code Indication with flashing LED on receiver unit Schedule functions: Countdown timer with on, off & repeat off settings. Hi Power: Extra strong air flow for quick cooling. Energy Saving Mode: For night operation with reduced fan speed and unit shut off

after 1, 3, 5 or 9 hours. Silent Mode: the indoor unit can operate at extra low speed with very low noise level.

Wired Remote controller for Air to Air Heat Exchanger Toshiba Model References: NRC-01HE

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The remote controller(s) shall be surface mounted and hard wired to the Air to Air Heat Exchanger unit(s) via the AB connections, to provide the user with either local individual control of the air-conditioned space, or group control of up to 8 air to air heat exchanger units. The controller shall be manufactured in ABS plastic with a liquid crystal display (LCD). A temperature sensor is to be incorporated within the casing to allow the user to set the sensing point at the controller, or at the indoor unit. The controller shall enable the user to interrogate the system and display an alphanumeric fault code in the event of system malfunction. The controller shall be able to provide control or indicate status of the following functions:

Start/stop. Switchable ventilation modes (Automatic/Air to Air/Normal) Switchable ventilation air volume (Extra-high/High-Low) Central control address. Auto-restart. Temperature sensor in use. Two remote controllers can operate a single Air to Air Heat Exchanger.

Schedule Timer Controller Toshiba Model References: RBC-EXS21TLE The schedule / weekly timer can be wall mounted and manufactured in ABS plastic with an LCD display. The controller shall provide 3 on/off periods per day in a 7-day cycle with a day omit capability. In addition the controller shall be able to auto-restart the whole system after a power failure and have 100 hours backup memory.

(Weekly Timer Mode) A weekly timer shall be connected to either the central controller, Smart Manager controller, and/or each standard remote controller. It should be connected via a dedicated 4-core lead supplied with the timer.

(Schedule Timer Mode) A schedule timer shall be connected to either the central controller, Smart manager controller or a local standard remote controller for its power ONLY. It shall be connected to the air conditioning systems via the U3/U4 network for its communication.

TCC-Link Central Controller Toshiba Model Reference: TCB-SC642TLE2 A central controller shall be recess mounted and hard wired to the outdoor unit(s) via the U3/U4 network, to provide the user with individual control of up to 64 master indoor units. The controller shall be manufactured in ABS plastic with a liquid crystal display. It shall be supplied from a 220-240 V ac 50 Hz power source. A maximum of 10 central control devices must be able to be fitted to a single control network (U3/U4). It must be possible to switch the controller on and off from a remote source via a volt-free contact connected across the A series terminals. The B series terminals must provide operation and general fault outputs. The controller shall enable the user to interrogate the system and display a hexadecimal fault code for each master indoor unit in the event of system malfunction.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The central controller shall display status and provide control of the following primary functions for each master indoor unit:

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). Fan speed (high, medium, low & auto). Louver position (where applicable). Filter check. Automatic or manual central control addressing – with the further option to provide

this from the controller. Four levels of remote controller permit/prohibit functions.

In addition the central controller shall facilitate the use of all remote controllers (RBC-AMT32E/RBC-AS41E/RBC-AMS51E-ES/RBC-AS41E) to provide the user with localised control of the air-conditioned space. When standard remote controllers are used, each master unit must have the capability to control up to 7 slave units if required (all will operate to the same conditions as the master unit). The central controller can restrict the operation of local controllers, preventing changes being made to:

On/Off settings. On/Off, Mode and temperature settings. Mode and temperature settings. Mode settings.

When used in conjunction with a weekly timer (RBC-EXW21E) the following configurable relationships must be available:

Indoor units are turned on/off with the weekly timer and remain open to local override for one time period.

Indoor units are turned off with the weekly timer and rely on local override to operate for one time period.

Indoor units have on/off control disabled with the weekly timer and rely on local override to operate for one ON time period.

Indoor units are stopped and have on/off control disabled with the weekly timer and rely on local override to operate for one ON time period.

Indoor units have all functions disabled with the weekly timer and rely on local override to operate for one ON time period.

Indoor units are stopped and have all functions disabled with the weekly timer and rely on local override to operate for one ON time period.

SMART Touch Screen Controller The Toshiba Touch Screen Controller provides a modern compact approach to management control technology utilising easy to use icons and simple navigation to deliver precise control and data analysis. The Toshiba Touch Screen Controller is simple to install and configure and offers three levels of operation and are password protectable. The Toshiba Touch Screen controller features a

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

built-in web browser interface, unit status, unit enable and disable, time and alarm management control and fault indication. Features Built in Web Browser Back-up and Restore Customisable appearance Multi-language preference Alarm Settings Unit setup, status and inhibit Programmable time and date events Maximum 64 Indoor Units/Groups and 16 Outdoor systems can be connected TCB-PCNT30TLE2 Network adapter required for connection of DI/SDI to provide TCC

Link Connection. Please note: This device is limited to standard network restrictions applied to the TCC Link network with a maximum indoor unit count of 64 indoor units. TCC-Link Central Smart Manager with data analyser Toshiba Model Reference: BMS-SM1280ETLE A Smart Manager central controller shall be recess mounted and hard wired to the outdoor unit(s) via the U3/U4 network, to provide the user with individual control of up to 128 indoor units. The controller shall be manufactured in ABS plastic with a liquid crystal display. It shall be supplied from a 220-240 V ac 50 Hz power source. A maximum of 10 central control devices must be able to be fitted to a single control network (U3/U4). The controller shall allow the possibility of remotely connecting to a PC. The PC shall be able to control all functions of the controller via a suitable Web browser, including 24 hour / 7 day timer schedules. The Controller shall allow connection of suitable energy monitoring kits (RBC-EM1-PE), via a relay interface (BMS-IFWH5E). – Up to 4 No. relay interfaces will be connected to a single smart manager controller. The controller shall also allow for the connection of a Digital Input/Output Relay Interface for the connection of ancillary equipment. The Controller shall allow the possibility of switching the system(s), to which it is connected, on and off from a remote source via a volt-free (or pulse) contact connected at the rear of the wiring panel. It must also provide the facility to shut down the entire system(s), to which it is connected, via a suitable signal (volt free or pulse) from a local fire detection panel. A manual restart of the systems after the ‘all clear’ is given by the local fire alarm panel, will be required by the user. The Controller shall also provide operation and general fault outputs, via a closed contact circuit (for both ‘system running’ & ‘system stop fault’), also at the rear of the wiring panel.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The controller shall enable the user to interrogate the system and display a hexadecimal fault code for each master indoor unit in the event of system malfunction. The central controller shall display status and provide control of the following primary functions for each master indoor unit or group :

Start/stop. Operating mode (auto, cool, heat, dry, fan only). Temperature set point (18°C to 29°C). Fan speed (high, medium, low & auto). Louver position (where applicable). Filter check. Automatic or manual central control addressing – with the further option to provide

this from the controller. In addition the central controller shall facilitate the use of remote controllers (RBC-AMT32E , RBC-AMS41E, RBC-AMS51E-ES or RBC-AS41E) to provide the user with localised control of the air-conditioned space. When standard remote controllers are used, each master unit must have the capability to control up to 7 slave units if required (all will operate to the same conditions as the master unit). The Smart Manager central controller can restrict the operation of local controllers, preventing changes being made to:

On /off settings. On/off, mode and temperature settings. Mode and temperature settings. Mode settings.

Web Browser Control Software The controller can be connected to a computer via an Ethernet cable and accessed via a fixed IP address to view the units. The layout can be selected in terms of Area Name, Floor Name or Tenant Name. Other key features are:

On/Off, Mode and temperature settings. Advanced Operation and Master Schedule functions available Up to 4 users can be connected at any one time. Up to 32 User accounts can be programmed with different levels of access. Error Code history. Energy monitoring and report creation functions available

Additional devices with use with BMS-SM1280ETLE Toshiba Model Reference: BMS-IFWH5E The energy monitoring relay interface connects to the RS485 Network and provides a means of interface to the pulse power meters. Up to eight power meters can be connected to each relay interface. Toshiba Model Reference: BMS-IFDDO2E2

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The D/I module connects to the RS485 network and provides 8 inputs and 4 outputs, which could be used to interface a fire alarm or a room occupancy sensor. The D/I module output could be used as a means of remote fault indication to another system Power Meter Locally Procured Switching HUB and LAN cable Locally Procured PC for Web Browsing Control & Energy monitoring functions Locally Procured Lon Works® Interface Toshiba Model Reference: TCB-IFLN642TLE A Lon Works® Interface shall be hard wired to each header outdoor unit via the U3 & U4 network, to enable the user to individually control up to 64 indoor units. The Lon Works® interface can provide 28 network variables for the sending of control commands and receiving unit information. Multiple interfaces may be connected to a single TCC-Link network and addressed using switches on the device. This is to enable ease of installation, for example buildings with separate areas or where one interface may be used for each area or floor. The interface shall enable the PC to display status, diagnostics by unit number and provide control of the following primary functions for each master indoor unit: - Mode of Operation (Auto, Cool, Heat, Fan Only)

Temperature Set Point (18°C to 29°C) Fan Speed (High, Medium, Low & Auto) Louver Position (Where applicable)

On/Off The Lon Works® gateway is a device that allows the Toshiba indoor units to be connected to a Lon Works® based BMS.. In addition, the interface shall facilitate the use of Remote Controllers (RBC-AMT32E, RBC-AMS41E, RBC-AMS51E-ES or RBC-AS41E) to provide the user with local control of the air-conditioned space. When standard remote controllers are used, each master unit must have the capability to control up to 7 slave units if required (all will operate to the same conditions as the master unit).

Each Toshiba Lon Works® Interface can be connected to up to 64 indoor units on the TCC-Link Central Control Network.

Up to 16 refrigerant systems can be connected to each Lon Works® device on a single TCC-Link Network.

Up to 10 TCB-IFLN642TLE Interfaces can be connected to a single TCC-Link Network

Windows® Package & Windows® Gateway Toshiba Model References: RBC-WP1-PE TCB-IFLN642TLE

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

A Windows® Package (RBC-WP1-PE) shall be used in conjunction with a LonWorks Gateway (TCB-IFLN642TLE). This is the front-end software package that controls all aspects of the air conditioning systems software is installed on a PC. The Windows® Package shall enable the user to control up to 1024 individual indoor units, and via the Gateway be capable of adjusting, managing and displaying all the following control functions: Mode of Operation (Auto, Cool, Heat, Dry, Fan Only)

Temperature Set Point (18°C to 29°C) Fan Speed (High, Medium, Low & Auto)

Louver Position (Where applicable)

On/Off Fault Code Diagnostics, (Hexadecimal code with short explanation of fault for quick diagnosis) Sensor Data Indoor Unit can be prohibited On/Off Control Only Multiple Time Scheduling; (24 events a day) Frost Protection Energy Monitoring (RBC-EM1-PE power meter is required for this function) In addition local control may be provided to any or all zones by the use of Remote Controllers (RBC-AMT32E, RBC-AMS41E, RBC-AMS51E-ES or RBC-AS41E). When remote controllers are used, each master unit must have the capability to control up to 7 slave units if required (all will operate to the same conditions as the master unit). The controls software shall also enable the user to display unit locations via site specific floor plans and transmit system alarms via the following media types: - Fax, SMS, Modems, E-mail and Pager. The Interactive Intelligence software tool is a Building Management Control software designed for use on the Lon Works® network protocol and can not only be used to control Toshiba Air Conditioner systems but also any building system that is required by the client to be controlled(i.e. Lighting, security, etc…) The following Interactive Intelligence software provides a means for the Toshiba Leak Detection and overall control of the VRF systems to be monitored & controlled from a central point. The format and visual appearance of the software can be set up to however the end user wishes to view this with the following levels of access to be set. Level 1 - Monitoring all areas only with no ability to change Level 2 - View all areas and enable changes to be made Level 3 - Administration or Engineering Access Level – Full ability to monitor, change and see recorded data regarding the performance of the system Additional Features

Connection to R410A equipment using TCB-IFLN642TLE Connection to R407C equipment using RBC-WG1-PE Remote access available using RBC-IK1-PE Integration with other site equipment using RBC-DI1-PE Digital Input/Output device

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Linked to Toshiba Leak Detection to monitor the systems connected. To enable the Windows® Package to be installed the following minimum system requirements shall be provided either by the end-user or the installer: - P4 2GHz or Equivalent 20G HDD (Minimum) 512M RAM (Minimum) Full size case to accept a Standard size PCI card (Not Mini PCI/PCIe) Windows XP professional or Windows 7 Professional 32Bit Version USB port For Dongle Toshiba Controls Reference RBC-WP1 Interactive Software 1No per 1024 Indoor Units TCB-IFLN642TLE LonWorks Gateway 1No per 64No Indoor Units (Typically to help with system addressing apply 1No Interface per floor) Note:- To cover the customisation set up of the Interactive Software as an initial cost please allow the following sub for software configuration. This allows for 1 ½ days to cover the time required to set up the WP1. Software Configuration £1,000 Exc VAT (Any additional time to be charged at £620 per day). Energy Monitoring Kit Toshiba Model Reference: RBC-EM1-PE Energy Monitoring kit(s) shall be fitted and used in conjunction with the Windows® Package and LonWorks Interface(s) to provide a means of calculating total power consumption of the air-conditioning system, broken down by indoor unit. Using this data the Windows® Package can generate bill reports to specific requirements and export data to billing software or an external site. Each kit consists of a power meter and a set of current transformers that are to be placed on the supply cables of up to six outdoor units. One power meter kit for each refrigerant circuit Please note: One power meter kit for each refrigerant circuit. Digital Input/Output Interface Toshiba Model Reference: RBC-DI1-PE The RBC-DI1-PE is a module that connects to the Lon Works® network that links backto Windows Interactive Intelligence software. The module has 8 digital inputs and eight relay outputs. These inputs can be used to control external plant or accept inputs from other plant. The relay outputs can also enable external plant in conjunction with the AC or plant which is independent.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Please note: Each device requires a power supply Each device has a limit of eight inputs and eight outputs. Black Pear Controller Toshiba Model Reference: RBC-BPB1 BACnet Interface RBC-BPM1 Modbus Interface RBC-BPT1 Trend Interface The Black Pear Toshiba HVAC controller is the most versatile connecting straight onto the U3/U4 network. The interface has an integrated LCD display which can provide an engineer’s interface for local control removing the need for a Central controller and separate interface. The units will operate on systems with or without a central controller and supports Modbus, BACnet and Trend protocols. The indoors units can easily be configured by using the integrated keypad in the event of a BMS failure in providing and enabling continuous communication. Features

BACnet I/P Modbus RTU or I/P TREND Via and Outstation Maximum 64 indoor units/groups and 16 outdoor systems can be connected TCB-PCNT30TLE2 Network adaptor required for connection of DI/SDI units.

Minimum required equipment for BACnet Black Pear RBC-BPB1 BACnet controller Sourced from TOSHIBA TCS-Net Relay Interface TCB-PCNT30TLE2 Sourced from TOSHIBA BACnet Control System Local supply Minimum required equipment for Modbus Black Pear RBC-BPM1 Modbus Controller Sourced from TOSHIBA TCS-Net Relay Interface TCB-PCNT30TLE2 Sourced from TOSHIBA Modbus Master Device Local supply Upper Side Modbus Graphic Control System Local supply Minimum required equipment for Trend Control System Black Pear RBC-BPT1 Trend Controller Sourced from TOSHIBA TCS-Net Relay Interface TCB-PCNT30TLE2 Sourced from TOSHIBA Trend IQ3/4 outstation with spare memory Local supply Please note: The device is limited to standard network restrictions applied to the TCC Link network with a maximum indoor unit count of 64 indoor units. Intesis WIFI Network Controller Toshiba Model Reference: IS-IR-WiFi-1 For use with residential systems TO-RC-WiFi-1 For use with most VRF/DI/SDI systems

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Intesis WIFI controller is connected to A+B terminals on RAV and VRF products to enable control through the Internet using a PC, Tablet or Smartphone Features Control your air conditioner from anywhere with your Smartphone, Tablet or Computer Control and monitor: On/Off, Mode, Set Temp, Room Temp, Fan Speed &

Louvre(limited) Easy to install: Wall or desktop mounted Attractive Design ON/OFF status and mode indicated by LED light Automatic firmware updates The TO-RC-WiFi-1 is not compatible with the RBC-AMS51E-ES remote controller

Outside Unit Control Board Toshiba Model Reference TCB-PCMO4E An additional PCB is to be fitted to each master outdoor unit to provide one of the following functions: a) Mode selection – This allows an external switch to determine the choice of operating mode.(Cool or Heat) b) Snowfall Fan Control When activated the outdoor unit fan will run independently of the compressor to prevent snow from settling on the unit when not in normal operation. c) On/Off External master start, or stop signals can enable, or disable each system. d) Set-Back When activated, the compressor and fan will be restricted in speed to provide a reduction in sound pressure level for a single unit from 59 dB(A) to 50 dB(A). Operation Output Control Toshiba Model Reference: TCB-PCIN4E An additional PCB is to be fitted to each master outdoor unit to provide an output signal based on the On/Off status of the connected units and an error output signal based on detected faults on the system. When connected to the SMMS-I product, the TCB-PCIN4E can be used to output the On/Off operation status of the compressors to output system operation rate. Start/Stop and Fault Interface Toshiba Model Reference: TCB-IFCB-4E2 Each indoor unit (master unit if grouped) is to be fitted with an interface to allow each indoor unit to be externally switched on and off by means of any volt-free external terminals. The

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

interface shall be linked to the indoor unit using CN61 on the PCB. This device must also have the capability of providing a positive indication of the operation of the indoor unit and signal any errors (system and indoor unit stopping faults) via externally fitted volt-free contacts. The interface shall be fitted in position near the relevant indoor unit. External switching components can include:

Time switch BMS Passive infra-red occupation sensor Auto restart Frost thermostat Fire alarm

Power Peak Cut Control Toshiba Model Reference: RBC-PCDM4E This device is designed for use where it is necessary to limit the electrical demand of systems at certain times. At certain time a signal can be sent to the device via a relay contact closure, which will limit the demand to pre-set levels. The Power Peak Cut accessory PC Board connects to connector CN513 of the Header Outdoor Unit PC Board. Sound Reduction and Demand Control for DI Toshiba Model Reference: TCB-PCOS1E2 The device is intended for installation on the DI outdoor unit range and has been designed to limit the outdoor unit noise production in cooling mode by 5dB, limit the maximum power consumption and give a compressor operation signal. This application connects to the CN510 connector of the outdoor unit interface PC board (DI only) Peak-Cut Control, Night Operation & Compressor Output for DI/SDI Toshiba Model Reference: TCB-KBOS2E The accessory is compatible with Series 4 DI and SDI equipment (excludes SDI 1.5-1.7 RS Units) and can be used to provide three possible functions. These are: Power Peak-Cut Control – Provides 3 levels of power saving levels Night Operation – Reduces the noise of the outdoor unit by restricting the fan and compressor operation. Compressor Output – Provides a non-voltage contact that is on whilst the compressor is operating. On/Off & Locking Lead Toshiba Model Reference:

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

RBC-SMCN61 This leads connects to any R410A Di/SDI or SMMS/SHRM indoor unit. This accessory allows the indoor unit to be enabled/disabled by a volt free contact closure. It also allows the remote to be locked to prevent the unit being switched on. This interface lead connects to the master unit on CN61 connector located on the indoor PCB. If this lead is to be used for the ON/Off function jumper J05 is to be removed. When the external contact is operated, all connected systems will be enabled or disabled, depending on whether the contact is opened or closed. Individual units cannot be omitted from the On/Off control process. Locking Lead Toshiba Model Reference: RBC-SMCN61L This lead will allow the ON/OFF functions of the remote to be locked in the ON or OFF position. The interface lead must be plugged into the CN61 connector on the indoor unit PCB. If the units are grouped the lead should be connected to the master unit. Timer Interface Lead Toshiba Model Reference: RBC-SMTI This leads connects direct to the following accessories: RBC-AMT32E NRC-01HE TCB-SC642TLE2 TCB-CC163TLE2

This lead is used to allow single or group of units connected to the above devices to be enabled or disabled by means of an external contact. The interface lead is connected to the CN02 connection. When the external contact is operated, all connected systems will be enabled or disabled, depending on whether the contact is opened or closed. Individual units cannot be omitted from the On/Off control process. Fan Interface Lead Toshiba Model Reference: RBC-SMFI This lead is used to allow an external ventilation fan to be controlled from an indoor unit. This lead connects to a digital inverter or VRF indoor unit. The interface should be mounted adjacent to the indoor unit and connected into CN32. The remote controller will require configuring to allow the operation of the auxiliary ventilation button.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

When the external contact is operated, all connected systems will be enabled or disabled, depending on whether the contact is opened or closed. Individual units cannot be omitted from the On/Off control process. Timer Interface Lead Toshiba Model Reference: RBC-IT4-PE This leads can be used with Toshiba RAV and VRF range of indoor units. The timer interface lead enables these systems to be externally switched On/Off by any volt-free external terminals rated at 230 volts AC. The device is connected to the indoor unit PCB via the CN06 socket on the 560/800 KRT models and the CN61 socket on all others models. This lead must be fitted to the header indoor unit. If fitted to slave/follower unit, incorrect system shut down may occur. When connected into CN06/CN61 the remote controller On/Off is disabled but the other functions Indicator Module Mode Toshiba Model Reference: RBC-SMIM2 This device is designed to give operational status of DI/SDI and SMMS/SHRMi systems. An indication is given as to whether the unit is heating, cooling or the fan is operating. The indication is given via a series of LED’s and the activation of a relay output. The volt free relay output terminals allow for remote interfacing with a control panel or BMS system. The device is to be located adjacent to the indoor unit and connected to the PCB via the CN60 socket. Indicator Module, On/Off and Stopping Fault Toshiba Model Reference: RBC-SMIM3 This device is designed to give operational and fault status of DI/SDI/SMMS/SHRMi systems. An indication is given as to whether the unit is heating, cooling or the fan is operating or whether the unit has a stopping fault. The indication is given via a series of LED’s and the activation of a relay output. The volt free relay output terminals allow for remote interfacing with a control panel or BMS system. The device is to be located adjacent to the indoor unit and connected to the PCB via the CN61 socket. Indicator Module On/Off, Stopping Fault and Unit Enable Toshiba Model Reference: RBC-SMIM4

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

This device is designed to give operational status of an air conditioning system and also to enable remote On/Off control, with a remote controller lock facility where required. There are LED’s on the interface giving a local indication of the RUN and FAULT status and relay outputs are provided to give a remote indication facility. There are also two input contacts for On/Off and On/Off lock. When the On/Off lock contact is mde the On/Off button on the remote controller is disabled. The device is to be located adjacent to the indoor unit and connected to the PCB via the CN61 socket. Jumper J01 must be removed from the indoor PCB to enable switching operation. Network Adaptor Toshiba Model Reference: TCB-PCNT20E The device is intended for use on the DI/SDI/SMMS/SHRM ranges of equipment and is designed to convert TCC Link to AI network protocol. This enables earlier types of control equipment to be interfaced with the current range. Network Adaptor Toshiba Model Reference: TCB-PCNT30TLE2 To facilitate the connection of Digital Inverter or Super Digital Inverter indoor units with the exception of indoor High Wall models SM-KRT-E. The adaptor is designed to enable Network devices such as central controllers and BMS systems to interface with DI/SDI systems. The device connects to the indoor unit PCB via socket CN50. VN Unit Interface Lead Toshiba Model Reference: RBC-VNL1 – Interface module for BMS Enable/Disable This lead will allow the VN unit to be controlled from volt free contact closures. Separate contacts are required for On/Off, remote controller lock, increased fan speed and damper position. The interface must be plugged into the CN705 connector on the VN unit PCB. If a lead is used with a remote controller it will operate in last one touched mode. If the VN units are grouped it can be connected to any VN unit in the group. BMS Interface Toshiba Model Reference: RBC-FDP3-PE RBC-FDP3-AHU Modified Software RBC-FDP3-PE

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

The RBC-FDP3-PE is a monitoring and control interface for Toshiba VRF and split ranges of air conditioners. The interface is compatible with all units that have a TCC-NET A+B remote controller network connection. No other network adapter cards are required. Functions HARDWIRED CONTROL Unit control achieved through resistance inputs. (Volt Free

Inputs) BMS INTEGRATION Unit control achieved through 1-10V voltage input integrated

with BMS control outputs REMOTE CONTROLLER Facility to individually lock and remote controller buttons

associated with unit control RUN/FAULT OUTPUTS Read-back of all indoor and outdoor fault codes and unit run

status DUTY STANDBY Run and standby rotation with run on fault and programmable

rotation period MODBUS RS485 Modbus Control and Monitoring Functions

RBC-FDP3-AHU The RBC-FDP3-AHU contains customised software to act as a controller for the RBC-AHU1 interface control panel and is connected using the A+B connections. The fixed resistance of the TA return air temperature sensor connection for the RBC-AHU1 interface must not be changed. DIP Switch Setting The FDP3-AHU can be enable to operate in two different modes depending on the position of DIP switch 1 setting. SW1 OFF Full Demand dependent on Digital Input SW1 ON Demand dependent on Input 0-10V Auto changeover Panel Toshiba Model Reference: RBC-AC1/RBC-AC2 The RBC-AC# is designed to be installed in computer rooms or communications rooms which are vital to the running of their organisation. Two or three units are installed and this panels switches these units over after one hundred hours or when one of the units goes into fault. When there is a fault it will also set off the alarm. It will also sense if the room becomes exceptionally hot and turns both the units on. If the temperature reaches a pre-set limit it will also activate the alarm. The panel also gives a volt-free output on any alarm condition to a BMS system. Refrigerant Leak Detection (To be used in combination with a WP1) Toshiba Model References: RBC-RD6 RBC-RD6-DI RBC-RP1

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

RBC-RI1 RBC-RD7 RBC-RD3 RBC-RCS1 RBC-RCS2 RBC-AIP1 RBC-AIP2 RBC-AIP3 RBC-AIP4 RBC-RD6 The RBC-RD6 Leak Detection System continuously monitors the air conditioning circuits and initiates the pump down of the refrigeration system in the event of identification of both a major or gradual refrigerant leak. The data is fed back to a CPU located in the panel. The RD6 incorporates 4 discharge line temperature sensors. On activation an audible and visual signal shall be received at the panel (and remotely if required). The outdoor unit shall be enabled and set to cooling mode, the liquid and discharge pipes isolated and pump down commences. The pump down duration is controlled via the CPU and on termination the suction line is isolated. The leak detection system shall operate via sensors which shall detect changes in both the refrigerant pressure and discharge temperature. This will signify a decrease in the levels of refrigerant gas. An audible and visual alarm shall operate and the system shall pump down the refrigerant and isolate the system using a set of motorised ball valves installed onto the suction, liquid and discharge pipes. Please note the addition of the sensors allows the CPU to detect the increased discharge temperatures associated with gradual refrigerant loss. Toshiba Controls Reference RBC-RD6 Leak Detection Panel 1 per VRF system Leak Detection Repeater Panel (RBC-RP1) The RBC-RP1 repeater panel is designed to work in conjunction with the RBC-RD6 refrigerant pump down panel and the RBC-RI1 room indicators. When activated by the RD6 panel a signal is sent out to the room indicators to give an audible and visual indication in the bedroom. Please Note that the negative sign to this type of control over having a room concentration sensor is that the alarm signal will be sent to all those rooms connected to that Repeater Panel. Toshiba Controls Reference RBC-RP1 Repeater Panel 1No per RD6 panel or VRF system Room Leak Detection Indicator (RBC-RI1) The room leak detection indicator is designed to work in conjunction with the RBC-RD6 Leak Detection Refrigerant pump down panel and the RBC-RP1 Leak Detection Repeater panel. When the RBC-RP1 is activated it provides a visual and audible indication that the RBC-RD6 monitoring the area has measured a refrigerant fault and initiated a pump down on the affected system.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Please note: A maximum of 10 room indicators can be connected in parallel to each out put on the RBC-RP1. Toshiba Controls Reference RBC-RI1 Room Indicator 1No per Bedroom RBC-RD7 Leak Detection Panel The RBC-RD7 Leak Detection Panel enables the isolation of an individual bedroom or occupied space without the need to fully shut down the air conditioning system. Operating in conjunction with any RBC-RCS# range of leak detection sensor, the RBC-RD7 Leak Detection Panel allows all other indoor units on the system to remain operational ensuring that comfort levels within the building are maintained. Toshiba Controls Reference RBC-RD7 Leak Detection Panel 1No per Bedroom RBC-RCS1(2)(Special) & RD3 Leak Detection Sensor The RBC-RCS Leak Detection Sensor PCB fits inside a flush mount electrical back box and is available with a range of cover plates or by using the RBC-RD3 with white plastic surround. The wall mounted concentration sensors are located within the areas to be protected. It interfaces with the VRF range of indoor units. It works by sampling the room air and detecting increase levels of refrigerant gas that exceed safety limits of 0.44Kg/m3 as stated in BSEN378 2012. Normal operation is confirmed by a green LED and fault indication is displayed by alternating red/amber LED. In the event of activation the sensor emits a visible and audible alarm within the bedroom and transmits an L30 alarm will be displayed on the local or/and the central control devices. Toshiba Controls Reference RBC-RCS#/RD3 Leak Detection Sensor 1No per Bedroom RBC-AIP1 Leak Indicator Panel The RBC-AIP1 Indicator panel is designed to work in conjunction with the RBC-RP1 (Repeater panel). Then the Toshiba RBC-RD6 (Refrigerant Pump Down panel) is activated the RBC-RP1 initiates the RBC-AIP1 panel to indicate a remote fault/alarm condition at a supervisory level and provides an output to the Windows Interactive Intelligence software package. Please note: Before applying power to the panel the battery must be connected. Toshiba Controls Reference RBC-AIP1 Leak Indicator Panel 1No per 4No RD6 panel RBC-AIP2 Leak Indicator Panel The RBC-AIP2 Indicator panel is designed to work in conjunction with the RBC-RP1 (Repeater panel). Then the Toshiba RBC-RD6 (Refrigerant Pump Down panel) is activated the RBC-RP1 initiates the RBC-AIP1 panel to indicate a remote fault/alarm condition at a supervisory level and provides an output to the Windows Interactive Intelligence software package. It is also possible to reset the RBC-RD6 panels from the Windows package through the RBC-AIP2.

TOSHIBA AIR CONDITIONING

TOSHIBA Super Modular Multi System Heatpump

Standard Specification

Please note: Before applying power to the panel the battery must be connected. Ensure the RBC-AIP2 panel is located in an occupied area. Toshiba Controls Reference RBC-AIP2 Leak Indicator Panel 1No per 4No RD6 panel RBC-AIP3 Leak Indicator Panel The RBC-AIP3 Indicator panel is designed to work in conjunction with the RBC-WP1 Interactive Intelligence Windows software package. In the event of the RBC-WP1 Interactive Intelligence software being shut down the RBC-AIP3 will activate a visual/audible alarm. The RBC-AIP3 panel has the ability to connect to the RBC-AIP4 alarm pnale to provide remote indication of the fault/alarm. Please note: The RBC-AIP3 must be connected to the PC running the RBC-WP1 Interactive Intelligence Window software. Toshiba Controls Reference RBC-AIP3 Leak Indicator Panel 1No per RBC-WP1 Interactive Intelligence Software RBC-AIP4 Remote Room Indicator The RBC-AIP4 remote room indicator is designed to work in conjunction with the Toshiba RBC-AIP3 Indicator panel. In the event of the RBC-AIP3 panel activation the RBC-AIP4 remote room indicator will signal an audible/visual alarm. Please note: The RBC-AIP4 must connect to the RBC-AIP3 Leak Detection monitoring panel of the associated refrigerant system Toshiba Controls Reference RBC-AIP4 Remote Room Indicator 1No per 1No RBC-AIP3 panel